Egg-stravagant

Spray Foam Magazine – February 2025 – The Spray Foam Magazine team is consistently energized by international projects, and we are particularly excited about this one, which is nothing short of “eggcellent.” We chatted with a prominent SPF and coating company in Russia to uncover the details behind their remarkable project featuring a massive egg structure.

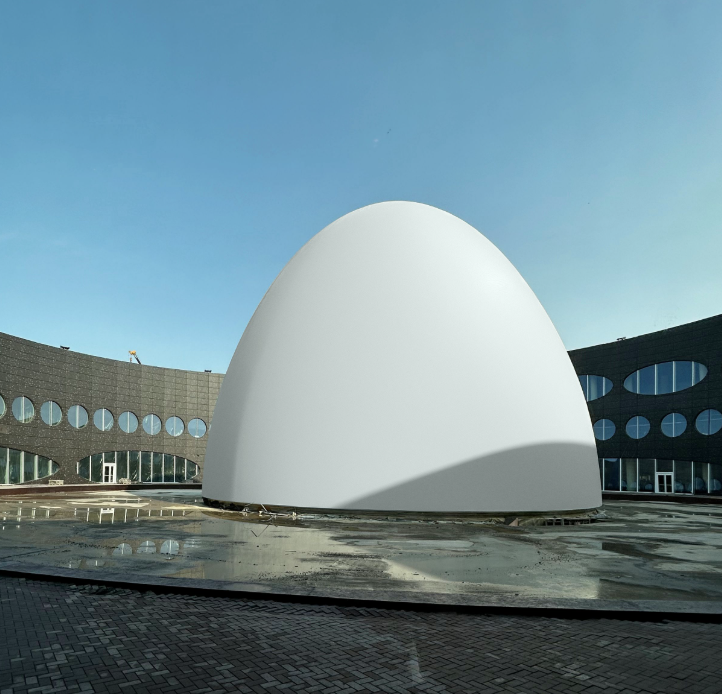

Claudio Silvestrin Architects, based in London and Milan, designed a stunning large egg to be installed at Elizovo International Airport in Yelizovo, Russia, situated 4,194 miles from Moscow. According to the architect, this structure draws inspiration from Ancient Greek mythology which sees the egg as the symbol of creation and new life. This, in renaissance wisdom, is beautifully represented in the Madonna of Montefeltro, a renowned image from Piero della Francesca’s early Italian Renaissance altarpiece. An egg hangs above the Virgin’s head, and while its precise meaning remains elusive, it may symbolize the birth of the New Testament or the purity and beauty of Mary. Nonetheless, the composition delivers a profound metaphysical impression, portraying an ideal frozen in time. The architect insisted on the surface using SPF to achieve this timeless feeling.

Claudio Silvestrin is no stranger to high-profile collaborations, having worked with industry icons like Giorgio Armani, Calvin Klein, Anish Kapoor, and Kanye West. His philosophy emphasizes difference over uniformity and quality over quantity, succinctly captured in his assertion: “I do not get out of bed unless I am going to create something exceptionally beautiful.”

Polysfera, a leading spray foam and coating company based in Moscow and helmed by CEO Konstantin Rubtsov, launched in 2009 it has carved a niche in thermal insulation using sprayed polyurethane foam. With state-of-the-art equipment and materials from Huntsman and BASF, Polysfera recognized a compelling demand for waterproofing and anti-corrosion solutions, leading to the creation of their Wotan® brand in 2021. This brand is now registered in four crucial markets: Russia, Germany, Turkey, and China, and operates seven fully equipped teams utilizing professional-grade equipment from Graco, GAMA, Blastrac, and Hilti.

The crew applied closed-cell Wotan Green Foam to the metal sheets of the egg exterior.

After the foam application was the challenging task of grinding the foam across 2,000 square meters of surface area.

The egg stands an impressive 82.02 feet tall and has a diameter of 98.43 feet, inspired by the Gorely volcano in Kamchatka. Situated at the heart of the airport, an event hall is planned for inside the egg, and an artificial pond is planned around the outside of the egg, which can be used as an ice rink in winter resembling a lake. After installing the metal sheets, seams remained, but the architect wanted to be seamless. The contractor responsible for the airport façade was fully aware of this demand, yet the architect rejected the notion of the metal panels having polyurethane sealant between them.

During a construction exhibition where Polysfera showcased its capabilities, the contractor discovered one of their polyurethane foam samples. This revelation sparked the idea to apply foam to the metal sheets, fulfilling the architect's vision for a seamless surface. It became clear that only foam spraying technology could meet the architect's stringent requirements without escalating costs or extending timelines.

Polysfera rigorously coordinated their Wotan® polymer coating system over six months, testing various degrees of sanding, polyurea thicknesses, and options for glossy, matte, and high-matte topcoats. This extensive documentation process was crucial to refining the project.

To deliver their equipment and materials, Polysfera undertook a monumental journey of over 6,213 miles. They secured an IL-76 aircraft for equipment transport and used their own vehicles to transport materials to Vladivostok, where the container was then shipped by sea to Yelizovo Airport. Upon arrival at the site, Polysfera prioritized safety checks and Personal Protective Equipment (PPE). This protocol included helmets, safety harnesses for high-altitude work, safety glasses, dust masks, and full-face masks with ABEK1 degree protection for the application of sprayable polyurethane foam and polyurea.

Polysfera's dedicated 12-person crew immediately ensured the aluminum sheets, which were 0.19685 inches thick, were impeccably clean. They proceeded to set up their equipment, featuring two Graco Reactor 2 E-XP2 units, a 206.69-foot hose, and Graco Probler Elite guns to apply their closed-cell Wotan® Green Foam at 1.18 inches.

After the closed-cell foam application, they tackled the challenging task of grinding the foam across a surface area of 2,000 square meters, reaching a maximum height of 25 meters. Once the surface was flawlessly smooth, they applied pure polyurea Wotan® e101 using two Reactor 2 H-XP3 units, along with the same 206.69-foot hose and Graco guns.

The crew then completed the process with the topcoat Wotan® WTC 305, primer Wotan® P09, and a special varnish to achieve a matte finish with Wotan® Finishlak. The primary obstacle Polysfera faced on this project was the weather; gale-force winds frequently stripped the protective coating from the airport, while strong gusts impeded spraying at both the top and bottom for safety reasons. However, despite the logistical challenges of transporting equipment and materials to the project site, the team executed this ambitious vision with exceptional skill and precision.

Deputy Director General of Polysfera, Sergey Bulgakov, said “We would like to thank all the participants in the construction of the Yelizovo airport in Kamchatka, and the architect for entrusting us with the implementation of his idea. Since this airport is international, welcome to Russia.”

CEO of the Polysfera company visiting the the facility during the foam application.

The final appearance of the surface and the view from the waiting room at the airport.

Disqus website name not provided.