Efficiency on Display

Spray Foam Magazine – February 2025 – When The New American Home (TNAH) 2026 makes its debut at the National Association of Home Builders (NAHB) International Builders’ Show (IBS) this February in Orlando, FL, lucky attendees will get the chance to step inside a luxurious showcase of sustainability, philanthropy, and high-performance building science. Located in nearby Winter Park, 2026’s TNAH is the pinnacle of design and energy efficiency. Playing a starring role from behind the scenes is Enverge open-cell spray foam, along with a supporting cast of other building materials, such as Fi-Foil radiant barrier and AeroSeal’s AeroBarrier. While visitors to the home may be immediately taken by the “WOW” factor of the sleek and modern architecture, aesthetics alone do not make a TNAH. It’s gotta be innovative.

Partners, Daniel Kennerly and Jim Krantz, with Orlando-based Alair Homes, are the official builders of TNAH 2026 construction of the 16,000-square-foot luxury home. Kennerly said the project is “unlike anything the program has ever seen.”

It’s a bold statement, and it’s also the truth. The mansion features six bedrooms and eight bathrooms, plus a 15-foot-deep basement with an 18-car parking garage and car elevator. Its exterior walls and roof deck are adorned with a one-three punch of Enverge open-cell spray foam, Fi-Foil radiant barrier, and AeroBarrier sealant system, enveloping the building in a tight seal. Topping off this energy-efficiency trio is an array of 108 solar panels situated atop the home’s flat roof to keep the home’s energy source sustainable.

Nearly every aspect of this year’s home, from its energy strategy to the funding model, breaks new ground in one way or another. For decades, The New American Home program has followed a consistent structure. Ordinarily, the TNAH builder would design a high-end speculative home, which it then builds using donated materials from manufacturers eager for visibility. The builder finances the entire project until construction is finished, then eventually sells the completed property to the highest bidder after showing off the completed build at the International Builder’s Show.

But this year, for the first time ever, the process flipped. Alair Homes had entered the running with a client already secured—a client with a message and a mission.

Alair’s client is none other than Jason Eichenholz, Ph.D, the founder and CEO of Relativity Networks, a tech business vying to redefine data center growth. Eichenholz is an entrepreneurial inventor with a heart as deep as his pockets. He also founded the non-profit Jonathan’s Landing in honor of his son Jonathan, an adult living with autism. Jonathan’s Landing strives to bridge the gaps and remove the obstacles to independent living that individuals with autism like Jonathan face. Eichenholz and his family will be living in the home, and also intend to use the space as a venue for the charity’s fundraising events. The Eichenholz family hopes that the publicity from its TNAH selection will bring awareness to the mission of Jonathan’s Landing.

“Jason asked the executive director of the National Association of Home Builders what would happen if he matched every donation dollar-for-dollar for charity,” Kennerly recalls. “They just stared at him. No one had ever made an offer like that.”

After the project was announced, contributions soared. Historically, the highest value of donated products for a New American Home hovered around $1.5 million. This year’s home has nearly doubled that total, reaching close to $3 million in contributions, shattering the program’s record. Those working on the construction side of things can’t help but be imbued with a sense of duty that goes beyond hanging drywall and spraying foam.

Alair broke ground on the project in October 2024 and is on track to finish by February 2026 after a whirlwind 14 months of dirt, sweat, and trying yet gratifying labor. Together with their preferred spray foam contractors, Synergy Foam, they’re raising the roof and the bar on what it means to be a luxurious, innovative New American Home.

A Strategic System for Energy Savings

Philanthropy may have expanded the project’s reach, but building science is what sets its performance apart from other magazine-worthy builds. Energy modeling for the home projects an unprecedented Home Energy Rating System (HERS) Index potentially lower than -40, placing it among the most efficient homes ever included in the program. The HERS Index begins at 100, and lower numbers indicate high energy efficiency. Having a negative HERS Score means this home conserves more energy than it consumes. Even its toilets are designed for efficiency!

It's quite an achievement, but it doesn’t hinge on a single product, but rather from a strategically integrated system of air sealing, insulation, and solar generation. And spray foam plays a starring role in the home’s energy savings.

“We knew from the beginning we wanted this house to be extremely tight,” Kennerly says. “Air quality, insulation, and the overall building envelope were priorities from day one.”

To execute the insulation package, Alair partnered with Synergy Foam, an Orlando-based spray foam contractor whom the builder has relied on exclusively for more than seven years. Naturally, Alair prefers to insulate all their projects using spray foam.

“We haven’t installed batt or blown-in insulation in any of our homes in a long time,” Kennerly says. “We advise every one of our clients that spray foam is the way to go.”

The builders marked the sections where foam will go. The Synergy Foam team will soon add four inches of open-cell spray foam to the framing on the exterior walls and roof deck (plus a few interior walls)

Kennerly cites several reasons the team continues to push clients toward foam. Benefits include cleaner installation, without loose fiberglass or airborne particulates. Foam’s dimensional stability is especially important in Florida’s humidity, where fiberglass can detach from framing. Plus, there’s the ease of future access. Since foam can be cleanly cut, future modifications to the wall’s internal components, such as electrical, plumbing, and HVAC can be done with ease.

With energy performance as the core mission, Enverge open-cell spray foam insulation was a natural fit. The project incorporates spray foam across the entire roof deck, all exterior walls, and even select interior walls for sound attenuation.

Many builders may have opted for closed-cell foam, which would have provided an air and vapor barrier on its own, explained Ryan Decker, Brand Manager for Amrize, Enverge’s parent company. But, using open-cell foam along with a radiant barrier and sealant was intended to balance sound attenuation with cost savings. Closed-cell foam alone doesn’t have the sound dampening qualities of open-cell, and in a home that will also double as an event space, these details matter.

The Enverge open-cell spray foam may play one of the leading roles in the energy efficiency showcase, but it certainly isn’t doing the job alone. Alair Homes paired the open-cell foam with Fi-Foil insulation products to maximize R-values while maintaining air tightness. It was a multi-step process, and Synergy Foam’s spray foam crew completed each step with style and professionalism.

With construction on a tight timeline and no room to negotiate the deadline, the spray foam team had to orchestrate their moves just so. To make the most of their time, they split into two teams to tackle the first and second floors simultaneously. The Synergy Foam crews filled the 2x6 exterior wall framing with four inches of Enverge open-cell foam, leaving a controlled two-inch air gap. Once the foam cured, they installed a Fi-Foil radiant barrier to create a reflective insulation layer that performs best when combined with foam. This high-performance duo of Enverge open-cell foam and Fi-Foil achieved approximately R-24 in the walls. The foam adhered cleanly to the wooden substrate, with minimal preparation involved.

Synergy Foam neatly filled in the framing with Enverge open-cell spray foam.

Synergy also utilized the same pair of products on the home’s roof deck to create a fully sealed unvented attic, improving thermal stability and helping to support the home’s negative HERS rating.

To reach ultra-low air leakage levels, Alair opted to add another layer of innovation: AeroBarrier, an aerosolized air-sealing system. The process pressurizes the entire home and releases an atomized sealant that is carried by airflow toward any leakage point, automatically sealing cracks up to a half inch wide. They used this product to tightly seal the entire house before adding the insulation envelope of foam and radiant barrier.

“It basically finds and seals every tiny opening,” Kennerly explains. “It’s amazing to watch, and it gets us incredibly close to the airtightness we’re targeting.”

Of course, no high-performance envelope is complete without a renewable energy source. In this case, the home features an array of 108 solar panels, generating approximately 43 kW— a production level that dwarfs that of typical residential installations and supports the project’s pathway to a negative HERS score.

Further upping the ante, the home also features a 15-foot-deep basement. Basements are a rarity in the state of Florida due to a shallow water table, which is typically only four to six feet below grade. But the lot that this home is built on naturally slopes approximately 21 feet toward a lake. Even better, Florida’s consistent soil temperature means the basement will help passively cool the home via geothermal insulation.

“Our geotechnical testing showed 16 feet before water,” Kennerly explains. “So, the client and architect decided a basement made perfect sense.”

Designing and building a home of this magnitude in just 14 months is already a staggering feat, but adding a 15-foot-deep basement escalates this build’s complexity to another level. Alair and their associates took every challenge in stride.

Beyond the jaw-dropping HERS Index of -40, the home boasts top green certifications, such as Energy Star, NGBS Emerald, DOE Zero Energy Ready Home, and Indoor airPLUS. This decorated list of certifications illustrates the futuristic possibilities of insulation technology and building science.

Spraying a New Standard

The New American Home 2026 is a case study in how collaborative contributions, high-performance materials, and visionary clients can elevate the standards of residential construction. For Kennerly and the Alair team, the success of this project only strengthens their commitment to spray foam as their default insulation strategy.

“We’ve used spray foam exclusively for more than seven years,” he emphasizes. “For us, it’s not an upgrade. It’s the standard. And this home is the best example yet of what’s possible because of it.”

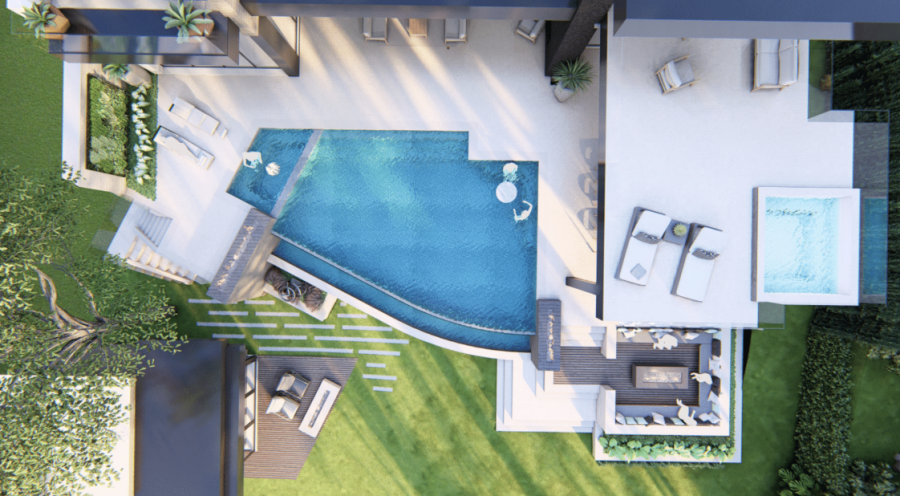

A rendering of the luxurious backyard of TNAH.

With negative-energy performance, cutting-edge air sealing, a meticulously engineered insulation system, and nearly $3 million in donated innovation behind it, Alair Homes has built a remarkable home and raised the bar for what the future of energy-efficient luxury construction can look like.

Disqus website name not provided.