Protective Coatings Tougher Than Elements: Ultimate Guide

Rutledge, GA — January 30, 2026 —The relentless demands of modern industrial environments require protective coatings tougher than the elements that can withstand extreme conditions while maintaining operational reliability. The escalating complexity of operational conditions across mining, chemical processing, and heavy manufacturing sectors has driven technological innovation toward ceramic-enhanced polymer systems engineered for molecular-level durability. These advanced solutions represent a fundamental shift from traditional paint technologies, incorporating sophisticated chemical architectures that resist degradation mechanisms through multi-layered defense strategies.

Understanding Molecular Engineering in High-Performance Coating Systems

Contemporary industrial protective coatings utilize cross-linking polymer networks that achieve significantly higher molecular density than conventional paint systems. These engineered formulations create three-dimensional chemical structures through controlled polymerization reactions, resulting in barrier properties that withstand extreme environmental conditions where standard coatings fail catastrophically.

Furthermore, the fundamental chemistry involves epoxide ring-opening polymerization with multifunctional hardener compounds, generating secondary hydroxyl groups that contribute to enhanced chemical resistance. This molecular architecture demonstrates superior performance across temperature ranges from -40°C to +200°C while maintaining structural integrity under mechanical stress.

Silicon Carbide Integration for Enhanced Hardness

Modern coating formulations increasingly incorporate silicon carbide ceramic particles rather than traditional aluminum oxide fillers. Silicon carbide exhibits a hardness rating of 9.5 on the Mohs scale compared to alumina's 9.0 rating, providing measurable improvements in abrasion resistance during high-friction applications.

In addition, the thermal conductivity properties of silicon carbide also enable superior heat dissipation through the coating matrix, preventing localised thermal degradation that commonly occurs with conventional filler materials. This characteristic proves particularly valuable in applications where equipment experiences continuous friction heating from abrasive materials, especially as mining industry innovation continues to advance.

Key Performance Differentiators:

- Molecular cross-linking density exceeding standard systems by 300-500%

- Chemical resistance maintaining functionality across pH ranges 1-14

- Temperature stability spanning 240°C operational windows

- Abrasion resistance surpassing 500 Taber test cycles

Specialised Coating Technologies for Industrial Applications

Different industrial environments require distinct coating chemistry approaches to address specific degradation mechanisms. The selection between epoxy-based, polyurethane, and polyurea systems depends on environmental factors including chemical exposure profiles, temperature cycling requirements, and mechanical stress patterns.

Moreover, as AI in mining operations becomes increasingly prevalent, the need for protective coatings tougher than the elements has become more critical to protect sophisticated equipment from harsh environmental conditions.

Two-Part Epoxy Systems for Chemical Resistance

Epoxy-based protective coatings excel in environments requiring exceptional adhesion strength and chemical inertness. These systems cure through cross-polymerisation reactions between epoxide groups and amine hardeners, creating dense molecular networks that resist solvent penetration and maintain barrier integrity during thermal cycling.

However, the curing mechanism generates secondary hydroxyl groups that undergo additional reactions with unreacted epoxide rings, producing a highly cross-linked polymer matrix. This chemical structure demonstrates glass transition temperatures typically ranging from 60-90°C, depending on hardener selection and resin molecular weight.

Performance Specifications:

- Adhesion strength: 2,000-4,000 PSI (ASTM D4541)

- Chemical retention: 95%+ after 1,000-hour immersion testing

- Service temperature range: -20°C to +120°C

- Cure time: 6-24 hours at ambient temperature

Polyurethane Elastomeric Solutions

Polyurethane coating systems provide superior flexibility and ultraviolet stability through their characteristic urethane linkage chemistry. The polymer backbone structure allows controlled molecular movement while maintaining protective barrier functionality, making these systems optimal for equipment subjected to thermal expansion and outdoor environmental exposure.

Consequently, the synthesis involves reactions between aliphatic polyisocyanates and polyol compounds, creating urethane bonds (NHCOO) that demonstrate exceptional elasticity. Advanced protective coating technologies like aliphatic isocyanate chemistry provide superior UV resistance compared to aromatic alternatives due to the absence of benzene ring structures susceptible to photochemical degradation.

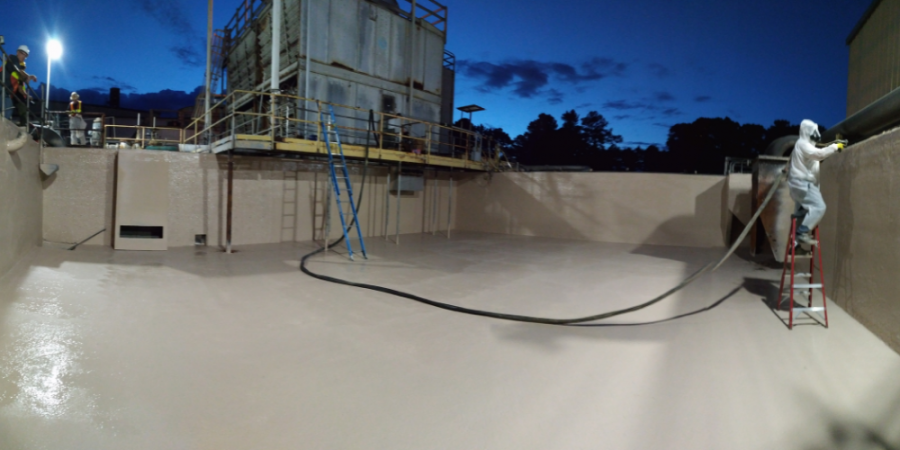

Rapid-Cure Polyurea Technology

Polyurea systems represent advancement in minimal-downtime coating applications where operational interruption costs exceed material expenses. The extremely rapid reaction between aliphatic isocyanates and amine compounds enables cure times measured in seconds rather than hours, facilitating immediate equipment return to service.

This technology proves particularly valuable for pipeline maintenance and tank lining projects in continuous mining operations where extended shutdown periods create cascading production losses. The reaction occurs at ambient temperature and humidity without requiring special environmental controls.

Optimising Film Thickness and Application Parameters

Coating thickness directly correlates with protective barrier effectiveness, but optimal performance requires precise control within specified parameters. Insufficient thickness creates micropores allowing moisture penetration, while excessive application generates internal stress leading to cohesive failure during service.

|

Application Environment |

Optimal Thickness |

Primary Considerations |

|

Chemical Immersion Service |

250-500 microns |

Permeation resistance optimisation |

|

Atmospheric Exposure |

150-300 microns |

UV degradation prevention |

|

High-Abrasion Zones |

300-750 microns |

Mechanical wear allowance |

|

Elevated Temperature |

200-400 microns |

Thermal expansion compatibility |

Surface Preparation Impact on System Performance

Substrate preparation represents the critical foundation for coating system durability, with surface cleanliness and profile directly affecting mechanical bonding strength. Research indicates that surface preparation accounts for approximately 80% of overall coating performance, with abrasive blasting to SA 2.5 standard (near-white metal) creating optimal anchor patterns for maximum adhesion development.

Furthermore, the SA 2.5 specification requires removal of all mill scale, rust, and foreign matter, leaving only minor discoloration on the steel surface. This preparation creates mechanical interlocking opportunities that contribute 40-60% of total adhesive strength, while chemical interactions and van der Waals forces provide the remaining bonding capacity.

Environmental Curing Considerations

Ambient temperature and relative humidity during application significantly influence polymerisation kinetics and final coating properties. Optimal curing conditions typically range from 10-30°C with relative humidity below 85%, ensuring proper cross-linking without moisture interference.

However, temperature below 10°C dramatically slows epoxy polymerisation rates, potentially preventing adequate cross-linking development within practical application timeframes. Humidity above 85% introduces moisture that competes with amine hardeners for epoxide functional groups, resulting in reduced cross-link density and compromised chemical resistance.

Critical Environmental Parameters:

- Application temperature: 10-30°C optimal range

- Relative humidity: Maximum 85% during cure

- Air movement: Sufficient to prevent solvent retention

- Substrate temperature: Minimum 3°C above dew point

Economic Analysis of Advanced Coating Systems in Mining

Protective coating selection requires comprehensive lifecycle cost analysis incorporating initial application expenses, maintenance intervals, and operational downtime costs. Premium coating systems often demonstrate superior economics through extended service life and reduced maintenance frequency, despite higher upfront investment.

Moreover, advanced ceramic-filled epoxy systems demonstrate service life improvements from 6 months to 18+ months in aggressive mining environments, representing a 300% performance enhancement. This improvement typically justifies premium coating costs through reduced maintenance labour requirements and increased equipment availability, particularly as data-driven mining operations become more sophisticated.

Return on Investment Calculation Framework

Comprehensive ROI analysis must incorporate multiple cost components to accurately assess coating system economics:

- Initial coating material cost per square metre

- Application labour and equipment expenses

- Surface preparation requirements and associated costs

- Scheduled maintenance interval extension value

- Unscheduled downtime cost reduction

- Equipment replacement deferral benefits

Service Life Extension Case Studies

Mining operations utilising advanced silicon carbide-filled epoxy systems report significant performance improvements in slurry pump applications. LOCTITE PC 7332, an advanced two-part epoxy system incorporating silicon carbide ceramic fillers, demonstrates up to four times greater resistance in slurry abrasion scenarios compared to standard protective compounds.

In sulphurisation and slurry pump environments, this technology extended service life from six months to over eighteen months, validating the economic benefits of advanced coating chemistry. The performance improvement directly addresses the dual challenges of chemical corrosion and mechanical abrasion that characterise harsh mining environments.

Quality Control and Performance Validation

Successful coating system implementation requires systematic quality control throughout the application process. Real-time monitoring of environmental conditions, material mixing ratios, and application parameters prevents defects that compromise long-term durability and performance.

Application Monitoring Protocols

Critical Control Points:

- Surface preparation verification (cleanliness and profile depth)

- Material temperature monitoring during mixing and application

- Mix ratio confirmation using electronic scales and documentation

- Wet film thickness measurement during application with calibrated gauges

- Dry film thickness verification after cure completion

- Adhesion testing per ASTM D4541 standards

Performance Testing Standards

Industry-standard test methods validate coating performance under simulated service conditions, providing quantitative data for specification compliance verification. Salt spray testing (ASTM B117), cyclic corrosion exposure, and chemical immersion studies generate reliable performance comparisons.

Consequently, ASTM B117 salt spray testing exposes coated specimens to continuous salt fog environments, accelerating corrosion processes to evaluate protective coating effectiveness. Test duration typically ranges from 500-2000 hours depending on expected service environment severity.

Key Testing Protocols:

- ASTM B117: Salt spray exposure testing

- ASTM G154: Accelerated weathering using fluorescent UV lamps

- ASTM D4541: Pull-off adhesion strength measurement

- ASTM D4060: Taber abrasion resistance evaluation

- ASTM D5402: Chemical immersion resistance assessment

Long-Term Performance Monitoring

Systematic coating condition assessment programmes enable data-driven maintenance decisions based on actual performance rather than arbitrary time intervals. Standardised inspection protocols, documentation systems, and trend analysis support optimised recoating schedules and continuous system improvement.

For instance, digital documentation systems facilitate trend analysis across multiple equipment installations, identifying patterns that optimise coating selection and application procedures. This approach aligns with modern mining leadership trends that emphasise data-driven decision making while maximising coating system ROI and minimising unexpected failures.

Addressing Common Application Challenges:

Environmental Contamination During Application

Moisture, dust, and chemical vapours can significantly compromise coating performance if present during application and initial cure. Proper environmental controls including dehumidification, dust suppression, and vapour isolation ensure optimal coating development.

Furthermore, dew point monitoring prevents moisture condensation on prepared surfaces that would interfere with coating adhesion. Substrate temperature must maintain at least 3°C above ambient dew point throughout the application and initial cure period.

Complex Geometry Coating Application

Mining equipment often features complex geometries including internal passages, sharp corners, and recessed areas that challenge conventional application methods. Specialised application techniques including airless spray, brush application, and injection methods address these challenges effectively.

However, airless spray equipment enables consistent film thickness application on complex surfaces while minimising overspray waste. Professional coating solutions emphasise proper spray pattern overlap and gun distance control to ensure uniform coverage without runs or sags that compromise protective performance.

Future Developments in Protective Coating Technology

Nanotechnology Integration

Emerging nanotechnology applications incorporate engineered nanoparticles that enhance specific coating properties without significantly increasing system viscosity or application difficulty. Nano-silica additions improve scratch resistance while maintaining optical clarity in topcoat applications.

Additionally, carbon nanotube reinforcement provides exceptional mechanical strength enhancement at extremely low loading levels, enabling thinner coating applications with equivalent or superior performance compared to conventional formulations. This technology aligns with mining decarbonisation benefits by reducing material consumption and environmental impact.

Smart Coating Systems

Advanced coating formulations incorporating colour-change indicators provide visual evidence of coating degradation or chemical exposure, enabling proactive maintenance scheduling. pH-sensitive dyes change colour when protective barrier properties become compromised.

Furthermore, self-healing coating technologies utilise microencapsulated repair agents that activate when coating damage occurs, automatically sealing minor defects and extending service life. These systems show particular promise for applications where access for maintenance is difficult or expensive.

Disclaimer: Performance data presented represents typical values under laboratory conditions. Actual service life and performance may vary depending on specific environmental conditions, application quality, and maintenance practices. Users should conduct application-specific testing to validate performance expectations for their particular operating environment.

Modern protective coatings tougher than the elements represent sophisticated engineering solutions addressing the most challenging industrial environments. Success requires a systematic approach encompassing proper specification, quality application, and proactive maintenance to achieve maximum equipment protection and operational efficiency. The evolution toward ceramic-filled formulations and rapid-cure technologies continues expanding application possibilities while improving performance reliability for mining and industrial operations worldwide.

Ready to Discover the Next Game-Changing Mining Technology?

Just as advanced protective coatings provide crucial advantages in harsh mining environments, early identification of breakthrough discoveries can provide investors with a significant market edge. Discovery Alert's proprietary Discovery IQ model delivers real-time alerts on significant ASX mineral discoveries, instantly empowering subscribers to identify actionable trading opportunities ahead of the broader market and position themselves for potential substantial returns from the next major breakthrough.

Published by Spray Foam Magazine

SprayFoam / Spray Foam Insulation

Disqus website name not provided.