Quality Control on the Jobsite

Spray Foam Magazine – February 2025 – In the competitive world of spray polyurethane foam (SPF) contracting, time is money. Every minute spent on paperwork or testing feels like a hit to productivity and profit margins. But here’s the reality: proper jobsite quality control (QC) isn’t just a formality—it’s a critical safeguard for your business. When installation issues arise, documented QC records can mean the difference between a quick resolution and a costly dispute and repair.

Beyond risk management, QC ensures your foam meets manufacturer standards for performance and safety. It optimizes yield, minimizes callbacks, and builds trust with clients.

Let’s explore three essential QC practices every SPF contractor should adopt.

1. Daily Work Records: Your First Line of Defense

Every SPF job, regardless of size, should have a daily work record. This isn’t busywork—it’s your insurance policy. These records capture critical jobsite data, including:

- Date and time of measurement

- Outdoor conditions: temperature, humidity, sky conditions

- Indoor conditions: ambient temperature and humidity

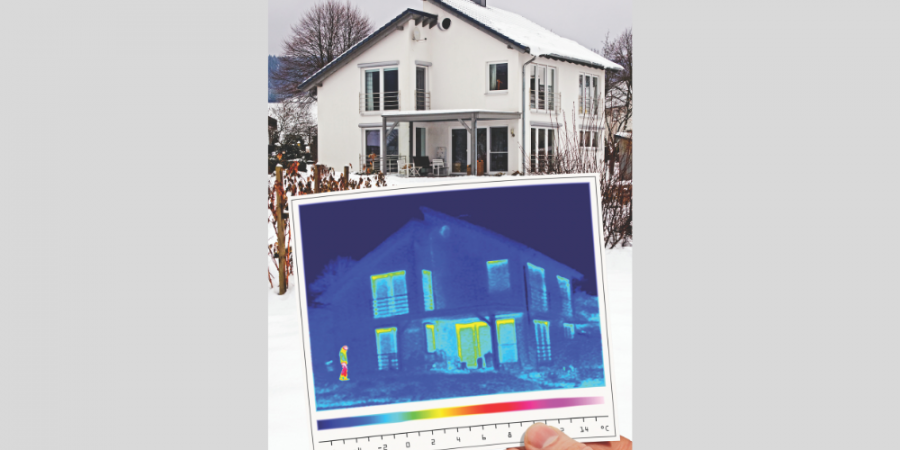

- Substrate temperature and moisture (using IR thermometer and moisture meter)

- Proportioner temperatures and pressures

- Material lot numbers

Best practice? Record this information at least three times during the day. Many manufacturers provide standardized forms, and modern proportioner equipment often logs equipment settings automatically. These records not only help troubleshoot issues but also demonstrate compliance with manufacturer guidelines.

2. Density Checks: Small Effort, Big Payoff

Measuring core density during installation may feel time-consuming, but it’s one of the most effective ways to prevent future problems. Out-of-spec density can signal potential shrinkage or odor complaints—issues that lead to expensive callbacks. Density checks also allow visual inspection of cell structure, giving you immediate insight into foam quality.

Contractors who monitor density a few times per day report fewer yield problems and better overall performance. Think of it as a small investment that pays big dividends.

3. Adhesion Checks: Stick With It

SPF naturally shrinks as it cools and cures, especially closed-cell foam. Poor adhesion can lead to cracking and delamination weeks after installation. A simple test? Remove a core sample:

- Clean removal with little foam left = adhesive failure (bad news)

- Difficult removal with foam residue = cohesive failure (good news)

- For more precise results, use a pull-testing device, though it requires additional prep and time. Good adhesion is critical for long-term performance—don’t skip this step.

- Why QC Is Non-Negotiable

Canadian spray foam installation standards (CAN/ULC-S705.2 and S712.2) and ABAA Quality Assurance Program (QAP) mandate QC procedures, including daily record-keeping and on-site testing. In the U.S., these steps aren’t required—but they’re considered best practice. QC documentation helps you:

- Minimize product failure risk

- Meet manufacturer performance standards

- Optimize foam yield

- Resolve disputes with solid evidence

Bottom line? Treat QC as an investment, not an expense. The time you spend today can save thousands tomorrow.

Direct any questions about this article to Rick Duncan at rickduncan@envelogic.com

Disqus website name not provided.