Clearing the Air

Spray Foam Magazine – Winter 2025 – As the Technical Director of the Spray Polyurethane Foam Alliance (SPFA), one of my ongoing responsibilities is responding to support line calls from the public.

A recurring concern I hear—often weeks or even months after installation—is about lingering chemical odors following interior spray foam or coating applications.

While odor perception can be subjective, in many cases these complaints are valid and traceable to chemical residues that persist despite proper installation practices. Even when contractors follow manufacturer guidelines for temperature, pressure, and substrate conditions, unreacted chemicals can remain in the foam and the surrounding air.

Proper ventilation is not just important, but essential.

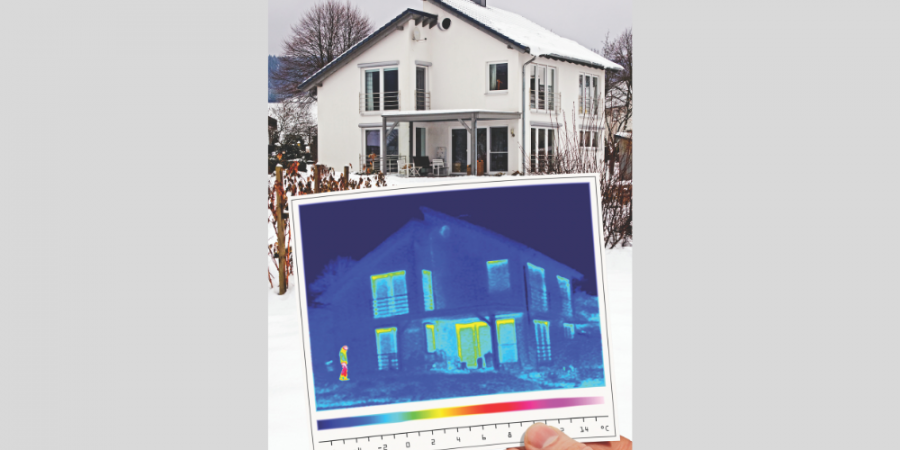

Spray polyurethane foam (SPF) has revolutionized insulation, offering superior thermal performance and air sealing. But with its benefits come serious responsibilities—especially when it comes to worker safety and indoor air quality. One of the most overlooked yet vital aspects of SPF installation is ventilation, both during and after application.

The Invisible Risk

High-pressure SPF application releases airborne chemicals at concentrations that can exceed safe exposure limits. Among the most concerning are MDI (methylene diphenyl diisocyanate), catalysts, flame retardants, and blowing agents. These substances pose risks not only to installers but also to building occupants if not properly managed.

According to OSHA’s Hierarchy of Control(1), the most effective way to eliminate workplace hazards is through elimination or substitution. However, when it comes to SPF, these options are off the table—the chemistry is non-negotiable. That leaves contractors with three critical tools: engineering controls, administrative controls, and personal protective equipment (PPE).

Engineering Controls: Contain and Ventilate(2) — Effective engineering controls start with containment of the spray zone and negative pressure ventilation to remove airborne contaminants. While ventilation alone may not reduce chemical concentrations to levels where PPE is unnecessary, it plays a crucial role in minimizing exposure and odor issues.

Administrative Controls: Train and Monitor — Administrative measures for SPF installation include:

Comprehensive training on chemical safety

Restricted access to spray zones

Emergency protocols for spills

Preventive maintenance of equipment

Clear safety signage

These practices(3) ensure that everyone on-site understands the risks and knows how to respond appropriately.

PPE: The Last Line of Defense — Installers must wear gear that protects the respiratory system, eyes, and skin from airborne chemicals, as outlined in the product’s Safety Data Sheet (SDS) and manufacturers installation instructions (MII). PPE is essential, especially during active spraying when exposure levels peak.

After the Spray: Why Ventilation Still Matters

Even when SPF is applied under ideal conditions per the MII —correct chemical ratios, temperatures, and moisture levels—the reaction between the A and B sides is never 100% complete. Unreacted chemicals remain in the foam and the air, and some can linger long after installation.

While MDI reacts with ambient moisture and becomes inert within a few hours, other chemicals like catalysts can release over time, especially in uncovered foam under roof decks during hot summer months. This process, known as diffusion, depends on the concentration difference between the foam and surrounding air. Lower airborne chemical concentrations using proper ventilation accelerate outgassing, reducing the risk of persistent odors.

Best Practices for Post-Application Ventilation

To mitigate these risks, manufacturers recommend continued ventilation for at least 24–48 hours after application. Ideally, ventilation rates should reach about 10 air changes per hour (ACH) or as high as practically possible. Controlled airflow helps clear residual chemicals and supports a safer, more comfortable environment for installers.

Bottom Line

Ventilation isn’t just a box to check—it’s a cornerstone of safe SPF installation. By combining smart engineering, rigorous training, and proper protective gear, contractors can protect their teams and ensure high-quality results. By prioritizing ventilation, contractors not only protect occupants and workers—they also uphold the integrity of the SPF installation and reduce the likelihood of callbacks and complaints.

Direct any questions about this article to Rick Duncan at rickduncan@envelogic.com

Sources:

“Identifying Hazard Control Options: The Hierarchy of Controls”, OSHA Publication https://www.osha.gov/sites/default/files/Hierarchy_of_Controls_02.01.23_form_508_2.pdf

“Ventilation Considerations for Spray Polyurethane Foam”, ACC-CPI Guidance Document. https://www.whysprayfoam.org/wp-content/uploads/2017/05/SPF-Ventilation-Guidance-v-3-2016.pdf

SPFA Contractor Health and Safety Resource Page https://www.sprayfoam.org/health-safety/

Disqus website name not provided.