Air Barriers, Vapor Retarders and the Roof In Between

SPRAY FOAM MAGAZINE – Buildings are designed to keep the outside weather out and the inside space conditioned in a desired way. This is done with control layers designed to stop the uncontrolled movement of water, air, heat, and moisture vapor. In order to be effective, they must be continuous on all six sides of the building enclosure – including the roof. The control layers may look a bit different on the roof than they do on the walls, but they are still needed to prevent the uncontrolled infiltration of water, air, heat, and vapor into the conditioned space. This includes the incorporation of air and/or vapor barriers into the roof assembly.

Uncontrolled air movement is a problem for two reasons: energy loss and moisture. According to “The Hidden Science of High-Performance Building Assemblies,” uncontrolled air movement accounts for 10-40 percent of heat gain or loss in our buildings (Environmental Building News, November 2012). This means additional energy must be used to maintain a constant interior temperature within the building, regardless of the climate zone in which it is located. The International Energy Conservation Code (IECC) now requires continuous air barriers on all sides of a building to reduce this unnecessary energy usage.

Air also brings uncontrolled moisture vapor into our building assemblies. One hundred times more moisture will come through a one square inch hole by way of air infiltration than will come through a 4 x 8 inch piece of gypsum by way of diffusion during the same time period. It is for this reason that it is more critical to ensure a building is properly sealed for air infiltration than to focus primarily on a vapor retarder in an assembly.

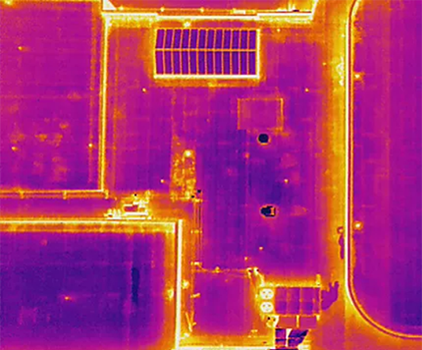

Thankfully, a lot of materials can perform the function of an air barrier, but it needs to be detailed correctly as part of an air barrier assembly. If the air barrier on the roof isn’t tied into the rest of the building, there is a risk of being able to take IR photos such as shown in FIGURE 1, where the warmer interior air is seen escaping around the entire roof perimeter illuminated as the warmer yellow and white.

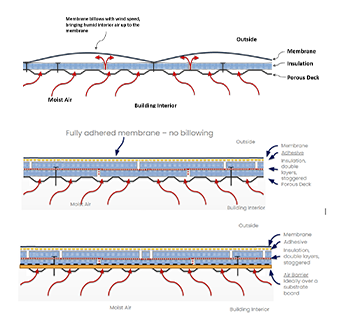

In most roof assemblies, the roof membrane is the primary air barrier. However, its effectiveness in providing a high performing air barrier depends on the rest of the assembly. FIGURE 2 contains three different roof assemblies that vary in how much air gets into the assembly from the interior of the building (think stack effect or hot air rising through a space). As the red arrows demonstrate, when a mechanically attached membrane is swapped for a fully adhered membrane, the air isn’t able to push up through the assembly and billow the membrane. When taken a step further by adding a dedicated air barrier to the roof deck, air (and its friends heat and moisture) are not able to get into the roof assembly at all. This further minimizes the wind uplift pressures on the roof assembly due to the internal forces of the building.

FIGURE 1 IR Camera image of building roof looking down showing temperature difference at roof perimeter indicating air loss (Image courtesy of Nexus)

FIGURE 2: Three different roof assemblies allowing different amounts of air and moisture.

This leads to the question of, “If I have a dedicated air barrier, do I need a vapor retarder too?” The answer is, “It depends.” Vapor retarders (not always a full barrier, so retarder is the correct term) will slow the migration of moisture vapor through your assembly, can lower condensation risks and also function as an air barrier if installed as such.

It is important to recognize that all materials have a vapor permeance which will slow or limit the movement of moisture vapor to some extent. The International Building Code (IBC) recognizes three classes of vapor retarders ranging from Class I at <= 0.01 perms when tested per ASTM E96 Method A to Class III being <= 10 perms. Materials with a permanence greater than 10 perms are classified as permeable and are not recognized as a vapor retarder. This means that designers must be cognizant of specifying a material designed to perform as the vapor retarder in a location and in a way such that moisture that comes by way of air movement cannot get inadvertently trapped between two materials with low vapor permeance, thus resulting in additional problems. This is illustrated in FIGURE 3 where the roof assembly has degraded as a result of long term trapped moisture. The best option is to install the vapor retarder on the warm side of the insulation and detail it as an air barrier to prevent moisture from getting trapped between two low permeance materials.

FIGURE 3: Moisture trapped between two Class I vapor retarders caused degradation of the insulation and roof deck. (Image courtesy of SGH)

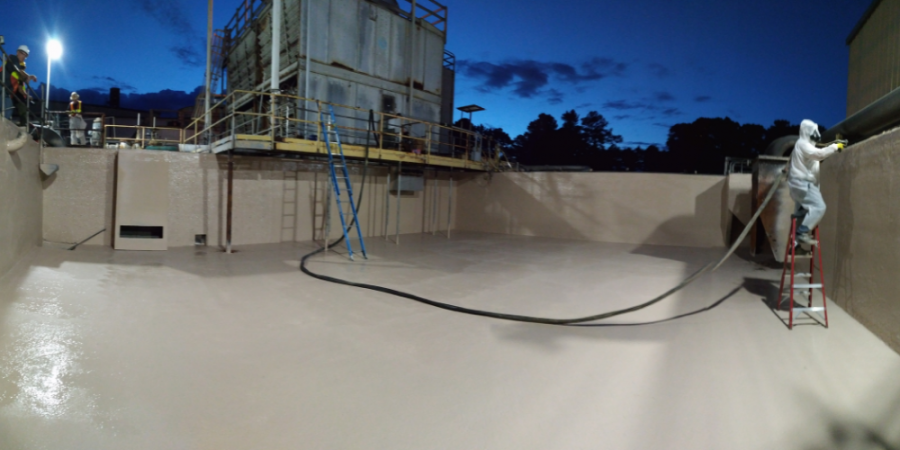

Vapor retarders can provide another benefit too. When Class I vapor retarders are installed on a concrete roof deck or on a cover board over a metal roof deck, they are able to function as a temporary roof during construction. Interior finishing is able to start in the building below until trades are ready to complete the roof. When the final roof is then installed, it can be done at a time when no further construction will be done on the roof. This can provide a clean, aesthetically pleasing roof as was required in the MGM Casino, MD project pictured on the previous page 22.

Air barriers are a code requirement for all new roofs based on the IECC, yet vapor barriers remain optional based on the needs of the project. However, in cases where there is a concrete deck, where there is a benefit of a temporary roof, or where there is a high vapor load on the interior of the building, vapor barriers can provide a benefit for the overall performance of the roof assembly.

*Spray Foam Magazine does not take editorial positions on particular issues; individual contributions to the magazine express the opinions of discrete authors unless explicitly labeled or otherwise stated. The inclusion of a particular piece in the magazine does not mean that individual staff members or editors concur with the editorial positions represented therein.

For use by SprayFoamMagazine.com & Spray Foam Magazine

Disqus website name not provided.