Round & Round the Polyurea Goes!

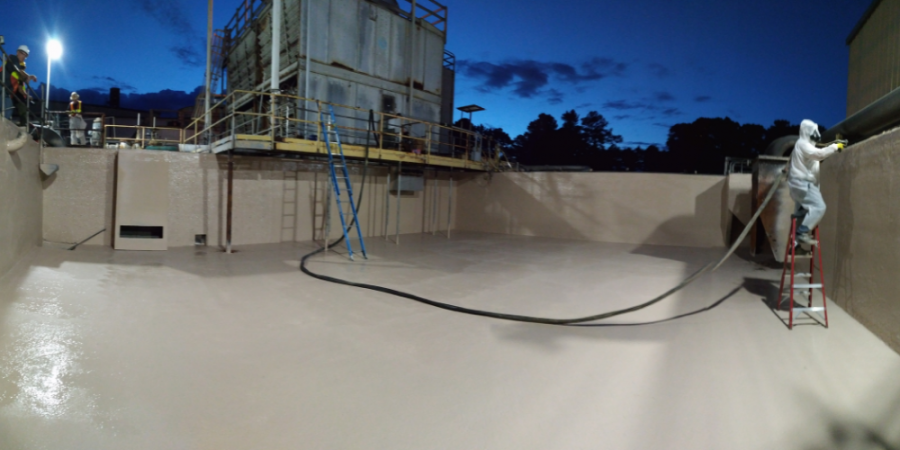

Spray Foam Magazine – Summer 2025 – It’s often asked, “what is the neatest polyurea spray project you have seen?” Ah…a great question and over the years there have been a variety that can fall into that category. But the first “neatest” was actually when the technology was sprayed for the first time back in 1986, almost 40 years ago. Boy, has time flown by!

Contrary to what Wikipedia had noted about polyurea spray, the technology was NOT developed in the 1990s as a wood edge coating system for institutional tables, etc. The technology was first demonstrated as a protective coating system for polyurethane spray foam, mainly used in roofing application work, and have “neat” uses grown since that time.

The truly neatest uses are the ones that combine creative, high-tech engineering, such as robotic technology with the high performance, fast setting thick-film elastomeric technology of polyurea systems. In recent years, examples of robotic application of the polyurea spray technology have been shown in various automotive OEM applications such as factory spray-in bedliner systems and ground effects/trim packages for example.

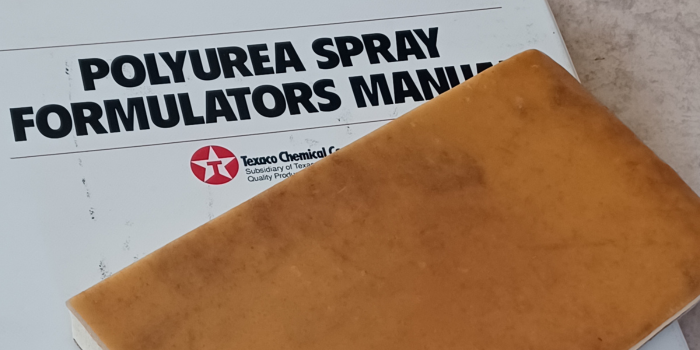

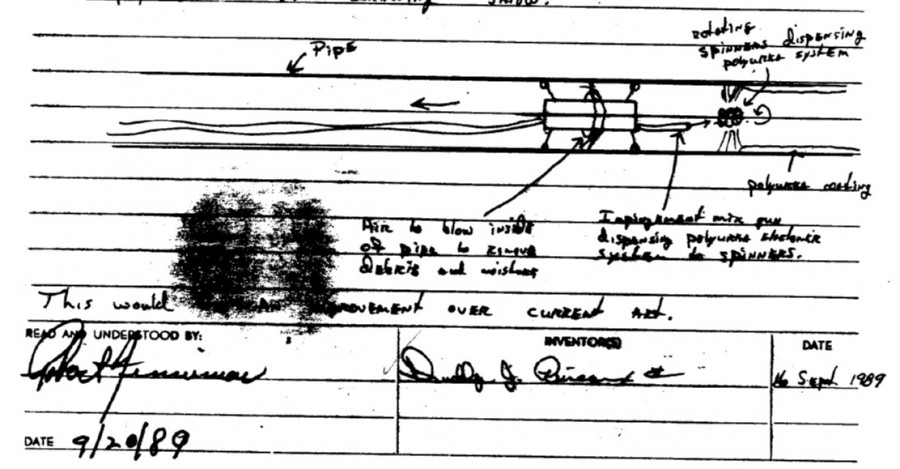

One of the most creative uses has been in underground trenchless technology work to address issues with our failing infrastructure throughout the world. Often referred to as SIPP: Spray-in-Place-Pipelining, this concept with polyurea spray was first disclosed and demonstrated back in 1989 at Texaco Chemical Company. Soon afterwards in the early 1990s, a company in the UK was actually performing some limited commercial work in this area. Sure, the spray heads may have been crude at the time, but it successfully worked to demonstrate this innovative process. And this was long before the Wikipedia table edge work.

Picture from Texaco Chemical Company Patent Suggestion AL 8824

Let’s briefly look at some of the challenges to this type of work as this is not like our conventional open area spray application work:

Proper Surface Preparation

It is well known that to achieve proper performance of an applied coating system, especially the fast set polyurea technology, proper and complete surface preparation shall be done. Just how does one prepare the surface of a length of 24-in (~61 cm) diameter pipe that is six-feet (~2 meters) or more below ground level? Most preparation work will depend upon the diameter of the pipe being lined and will use either a spin-blast type system or high-performance pig scrapers.

Some have noted in the past that for a structural spray applied lining, complete adhesion may not be required. However, this is a highly debated area of discussion with various opinions. For a truly elastomer system, complete adhesion is a requirement for overall performance!

Controlling the Internal Environment

In trenchless technology work, the pipes are in-ground, and typically that is a cooler and damp environment. As we have seen proper application methodology, the substrate temperature needs to be 5° F (3° C) above the dew point temp otherwise condensation will occur which can adversely affect adhesion of the applied material. Attention to this detail, and use of air movement and drying equipment is required.

Proper System Reactivity

Contrary to what some may think, a faster system is highly beneficial for these polyurea based systems. Since applying in a thick-film situation, and with overhead areas, a slow reactive system will exhibit significant dripping and runs. Even with a spinning disk type dispensing, gel times of the systems used here are still in that 6-8 sec gel time range.

Length of Pipe Structure, Bends and Access

In many cases for this underground work, hose bundles can be up to 600-feet (~180 meters). That is “easy” provided one has a straight run of pipe. The challenge comes when there are numerous 90- and 45- degree radiused angles and bends. The robot head assembly may pass easily, but then one will get binding of the hose bundles.

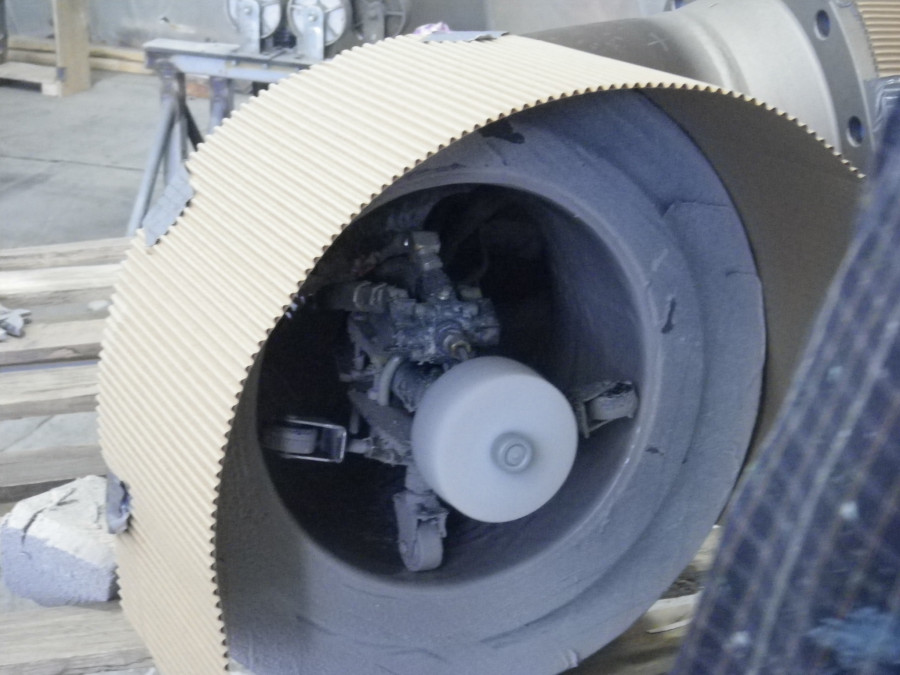

Availability of Commercial Spray Head, That Work

One of the main challenges has been the availability of commercial off-the-shelf spray heads for this work. Due to the fast speed of the thick-film polyurea systems, conventional spray heads that are used for conventional epoxy type system in that application area are not suitable. Most companies involved in this process fabricate their own spray head for use. Depending upon the size of the pipe, these spray heads may be a high-pressure static mix tube with hollow cone spray tip, dispensing on a high velocity spinning disk, or an actual rotating spray gun.

During the recent SFWW Rig Show event, prior to the SPFA Conference in Daytona, one such commercial robotic spray head, with video camera, was on display and demonstrated. An interesting note here, is that the equipment is designed and built by the same person involved in the initial work back in the early 1990’s in the UK!

Spinning disk inside 12-in (30 cm) diameter pipe, using an auto air purge spray gun

Of course, one can always pre-spray pipe or even the popular work in culvert linings. In 2012, a published report from Steel Market Development Institute for NCSPA – National Corrugated Steel Pipe Association, noted studies that if one “plastic coated” corrugated culvert pipe, a 75-year life expectancy can be noted. So, what is a great “plastic” to use here, well the polyurea spray technology of course.

Given these specific challenges, they can be overcome, and the technology does work. There is even an ASTM Standard related for pressure pipe, ASTM F 3182: Standard Practice for the Application of Spray-Applied Polymeric Liners Inside Pipelines for Potable Water. Additional work is in process via ASTM’s Work Group WK93327.

So yes, the truly “neatest” and unique ones are where we combine advanced technologies and robotics with high performance coating systems, that then address issues to improve our infrastructure system. A more detailed description of this technology and work can be found in an award winning technical paper and presentation from 2014, given at an SSPC Coatings+ Conference.

Published by Spray Foam Magazine

SprayFoam / Spray Foam Insulation

Disqus website name not provided.