Lift-Off to Long-Term Protection

Spray Foam Magazine – Summer 2025 – NASA, renowned for its stringent contractor selection process, has chosen Cool Roof Foam and Coatings to deliver a long-term roofing solution to protect its most valuable infrastructure and assets. Spray Foam Magazine spoke with Cool Roof Foam and Coatings to learn how their system meets NASA’s requirements.

About Cool Roof Foam and Coating

Founded in 2009, Cool Roof Foam and Coatings is a leading contractor specializing in energy-efficient commercial roofing solutions. The company has built a reputation for excellence by assisting businesses and organizations in need of high-performance, energy-efficient roofs. Owner and operator Peter Panagakos personally supervises all production aspects, demonstrating his commitment to quality workmanship and customer satisfaction.

Cool Roof offers an SPF roof system that is backed by a Category 5 hurricane wind labor and material manufacturer warranty. This level of protection is unmatched.

History Plays Its Part

Many iconic structures at NASA’s Kennedy Space Center are still in service, with seven designated as historic districts and one acknowledged as a National Historic Landmark. These structures are either listed or eligible for listing on the National Register of Historic Places.

As a result, the Center must adhere to various federal laws, regulations, and executive orders, including the National Historic Preservation Act of 1966 (NHPA). This legislation plays a crucial role in the preservation of Kennedy Space Center (KSC) and its historic properties. Consequently, any proposed changes or updates are closely scrutinized before receiving approval to proceed.

A Multi-Million-Dollar NASA Project

NASA sought to improve the roofs of several buildings at KSC by updating their aging modified bitumen and TPO roofs. Cool Roof has successfully completed numerous multi-million-dollar projects with NASA, utilizing its industry-leading spray polyurethane foam roof systems and silicone roof restoration coating on multiple buildings at KSC. To date, the Cool Roof crew has worked on 16 buildings, covering a total of 411,277 square feet, with more projects planned in the future.

In March 2025, the latest of these structures required a roof update. It was the building that houses two of the most significant artifacts in space exploration history—the Saturn V rocket and the Atlantis space shuttle.

Selected by NASA for Critical Roofing Project

NASA provided a loose project outline and Cool Roof followed up with a specific scope of work after conducting on-site evaluations. Mario Finazzo, Executive Sales at Cool Roof played a key role in securing this project through proprietary marketing strategies, a professional presentation, competitive pricing, and a reputation as a leading contractor in SPF roofing systems and silicone roof restoration coatings.

NASA is familiar with SPF, as a variation was initially developed by NASA engineers to create the world’s lightest and most durable insulation, capable of maintaining rocket fuel tanks at an astonishing temperature of -423°F.

Today, Cool Roof brings that same technology to commercial clients, delivering energy-efficient and highly durable roofing systems that significantly outperform traditional roofing materials.

Silicone Roof Restoration: The Smart First Option

“We always prioritize presenting silicone roof restoration coatings when a roof qualifies as a suitable candidate,” says Ted Dodson, Marketing and Sales Director at Cool Roof Foam and Coatings. “This solution offers significant cost savings, typically about one-third the cost of a complete reroof and causes far less disruption to building operations.”

Dodson points out that coatings are a viable option more often than many building owners realize. “In our experience, roughly 90% of the roofs we inspect qualify for a coating solution. Some may require additional preparation work, but most remain excellent candidates for restoration rather than replacement.”

For roofs that do need a full replacement, “We offer an SPF roof system that is backed by a Category 5 hurricane wind labor and material manufacturer warranty. This warranty guarantees, even in a Category 5 hurricane, that it will not blow off or leak. This level of protection is unmatched, especially considering that other roofing warranties are usually voided during named storms,” according to Dodson.

So far, Dodson confirms that Cool Roof is one of the only contractors capable of delivering this manufacturer’s hurricane warranty, which serves as a testament to their exceptional quality and strong performance relationship with the manufacturer.

Cool Roof Foam and Coatings has been trusted by NASA to complete the roofs on several of their buildings. Pictured here- A and B: Known collectively as the Atlantis Space Shuttle Building, C: The IMAX Theater, D: Journey to Mars/NASA Central, E: Formerly known as Chat with an Astronaut/The Mars Rover Vehicle Navigator, F: The Hall of Fame/Heroes and Legends Building.

Precision, Safety, and Respect for the Mission

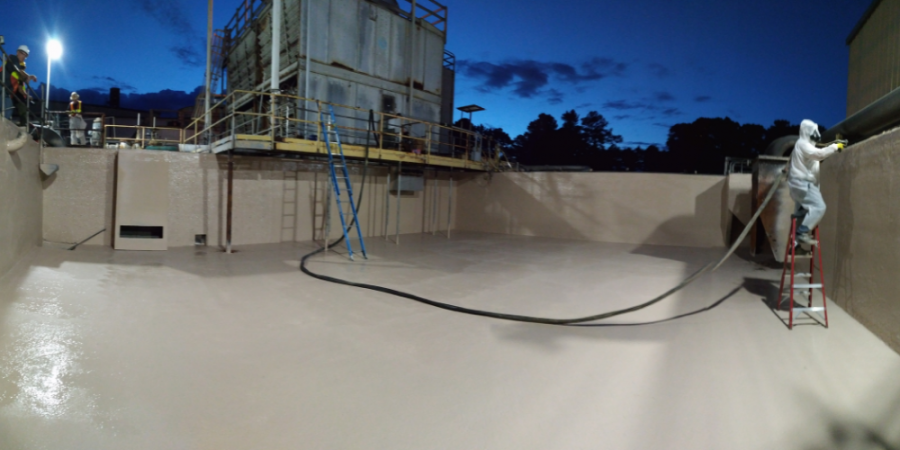

At KSC, Cool Roof deployed a dedicated team of approximately 35 crew members. Each morning, they arrived before dawn to stage materials, prepare work areas, and ensure that all operations were in place before the start of public visitation. Working within an active and high-security environment, the team followed strict protocols to minimize visual disruption for NASA guests and personnel.

Instead of removing the existing roof system, the crew performed all preparation and application work directly over the existing substrate, saving valuable time and eliminating the need for debris disposal. “Our goal was to make the project seamless, both technically and visually,” said Dodson. ‘We kept our work zones tightly contained to preserve the appearance and experience of this historic site.”

Due to the facility’s role as both a working government center and a tourist destination, the team often worked beyond regular hours, staying after the park closed to complete tasks that could not be done during visitor hours.

Safety was a top priority throughout the project. In accordance with NASA’s rigorous protocols, all team members were required to be fully tethered while working on the roof, regardless of parapet height.

While some structures had pre-installed anchor points, many did not, requiring Cool Roof’s safety team to engineer and install temporary stand-alone fall arrest systems. Additionally, while applying the SPF roof system and silicone roof restoration coating systems, the crew wore full PPE, including suits, respirators, and eye protection, ensuring complete compliance with industry best practices and site-specific regulations.

Meeting NASA’s Gold Standard

Cool Roof recognizes that few clients demand higher levels of security and safety compliance than NASA. With a significant portion of work at the Kennedy Space Center Visitor Complex, a site that hosts over 1.5 million guests annually, every action is subject to intense scrutiny and oversight.

“Our crews understood from day one that we were operating in one of the most tightly regulated environments in the country,” said Dodson. “Adhering to NASA’s safety protocols wasn’t just a requirement, it was a responsibility we took very seriously.”

From background checks to site access restrictions, every member of the Cool Roof team was fully vetted and trained to operate within NASA’s security framework. Crews were briefed daily on evolving safety conditions, and all movement, material staging, and application work was carried out with precision and full compliance.

“Working on a high-profile site like this reinforces the professionalism we bring to every job, no matter the size,” Dodson adds.

Professional-Grade Tools for a Mission-Critical Site

To minimize disruption to daily operations and ensure a safe, seamless experience for visitors, most of the spray foam application was conducted during early morning hours or after the Kennedy Space Center Visitor Complex closed for the day. During active hours, the Cool Roof crew maintained a clean and organized work environment. At the end of each shift, all equipment was thoroughly cleaned, securely stored, and fully concealed to preserve the visual integrity of the site.

For the foam application, the team used Graco H-40 plural-component proportioners paired with heated hoses to ensure consistent material delivery and optimal spray performance. Crews utilized high-pressure Extreme Pumps to apply Tropical Roofing Products’ 924 Eterna-Sil, a high-solids, bright white silicone coating.

To further enhance the quality of the installation, all buildings coated during the project are backed by a 15-year labor and material warranty from Tropical Roofing Products, a Soprema Group company. This warranty provides NASA with long-term peace of mind and emphasizes the reliability of the high-performance products selected for the job.

Speed, Precision, and Performance

Once the worksite was fully staged and all safety protocols were confirmed, Cool Roof began the spray application. The team applied NCFI’s EnduraTech™ Smart closed-cell roofing foam, building it up to a maximum thickness of three inches based on the roof’s drainage needs and thermal performance requirements. Up to 15 crew members were assigned to each roof, depending on the size and complexity of the project.

Tropical Roofing ETERNA-SIL 924 silicone coating was applied over the foam due to its long term UV protection and durability.

This flexible manpower allowed for efficient execution across multiple buildings while maintaining quality and safety standards. The foam was applied using Graco GX7 spray guns. “Our equipment choices are driven by performance and uptime,” explains Dodson. “We can’t afford downtime on a job like this, especially under NASA’s schedule.”

The team quickly transitioned to the coating stage, often within the same day. “Applying the silicone coating on the same day is critical to protect the foam from UV exposure and environmental moisture,” Dodson notes. “This fast turnaround also helps us maintain momentum without risking weather-related delays.” Throughout the process, crews maintained strict quality controls, including real-time thickness checks, adhesion testing, and detailed documentation of application conditions.

This attention to detail ensures long-term roof performance and meets the warranty requirements for both the foam and silicone systems. Each project is executed with precision, with the Cool Roof crews ensuring uniform foam thickness, consistent slope to drain, and clean transitions around penetrations, parapets, and flashings. “It’s not just about spraying; we treat every inch of the roof as a system because that’s what delivers long-term performance,” Dodson adds.

Why Tropical Eterna-Sil 924 Silicone?

After applying the SPF, the crew used Tropical Roofing Products’ ETERNA-SIL 924. This high-solid, pure 100% silicone coating is designed for long-term UV protection and waterproofing. “Tropical, now part of Soprema, is a local manufacturer with whom we’ve built a great relationship,” says Dodson. “Their service is exceptional, their pricing is competitive, and in our opinion, their products perform better than other brands we have used.”

The high-solids formulation of Tropical Eterna-Sil 924 allows for excellent build and coverage in fewer applications, reducing labor time while ensuring long-term durability. Additionally, the system includes an indefinitely renewable 15-year labor and material NO-LEAK manufacturer’s warranty, providing confidence and protection for mission-critical roofs.

Success

Some projects feel out of this world, and to land one of them, a contractor needs to have an exceptional reputation, team, and crew. “As a specialty roofing contractor committed to quality and innovation, we are honored to have been selected by NASA to help address their roofing challenges on such high-profile and historic structures,” said Peter Panagakos, President of Cool Roof Foam and Coatings.

“This partnership is a powerful testament to our reputation as the top-tier contractor in the industry. We take great pride in contributing to the protection of nationally significant buildings and artifacts.” Panagakos also emphasized the teamwork involved: “Our crew, staff, and sales team all rose to the occasion for this special client, just as we do for every client we serve.”

Published by Spray Foam Magazine

SprayFoam / Spray Foam Insulation

Disqus website name not provided.