A Bracket Breakthrough

Spray Foam Magazine – Late Summer 2025 – The team at Spray Foam Magazine (SFMT) is always intrigued by innovation within construction. Upon learning about a device that may have the potential to support contractors engaged in retrofit and barndominium projects, we felt it was important to investigate further. We reached out to the company responsible for this new device, and sought the expertise of Matt Risinger, host of “The Build Show,” to gain valuable insights into their appreciation for spray foam and this invention.

Edward Scherrer, the owner of InSoFast, is dedicated to advancing the construction sector. His journey began in custom home construction, where he swiftly cultivated expertise in insulating concrete forms (ICFs), radiant heating systems, and ultimately, InSoFast panels. Most recently, it is the innovative application of spray foam in InSoFast’s latest product that has attracted considerable attention and interest.

Applying continuous insulation, like foam, to a building's exterior effectively prevents thermal bridging and boosts energy efficiency. However, achieving a seamless installation at critical transition areas—such as between foundations and walls or between walls and roofs—can be difficult due to alignment and thermal bridging challenges. InSoFast states that its new X-Bracket system offers a practical and economical solution to these issues. The system utilizes durable composite plastic brackets that securely fasten furring strips and siding, while also maintaining a continuous insulation cavity to improve thermal performance and minimize energy loss.

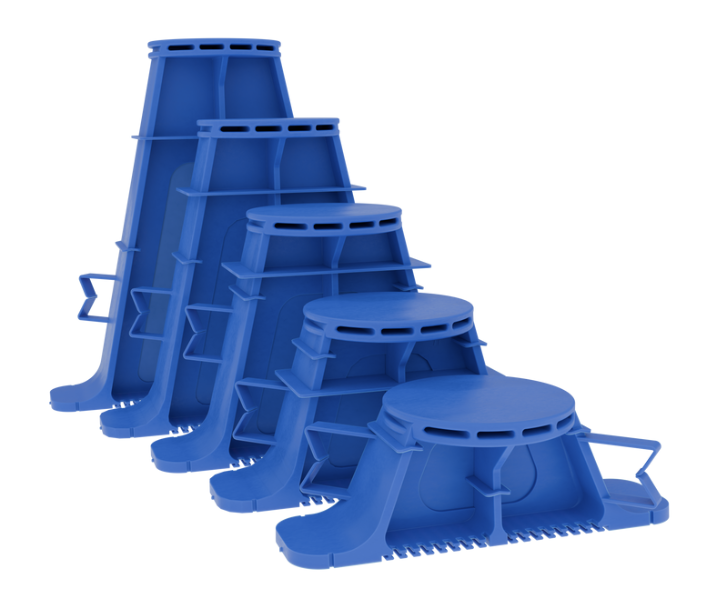

The team at InSoFast presents their X-bracket as a well-engineered solution capable of supporting insulation depths from 2.5 to 4.25 inches. This innovation streamlines the construction process by potentially reducing reliance on complex techniques, such as Larsen trusses or double-wall construction. Additionally, it appears to be a practical option for retrofitting, as it allows for the installation of continuous insulation over existing siding, which could enhance the overall performance of a building. InSoFast reports that their X-Bracket System has demonstrated impressive results in tests, handling wind speeds exceeding 200 mph and lateral loads above 300 psf when installed with specific fastening setups.

While their current focus is on simpler structures, they are looking forward to exploring its effectiveness in more complex designs soon. Each bracket is priced around $1.50, contributing to an assembly cost of $5 to $8 per square foot. Although the X-bracket may not become a widely adopted solution given that a basic layer of rigid foam can also satisfy code compliance it certainly holds promise as a valuable tool for certain projects.

Why did Ed Scherrer, product developer and owner of InSoFast invent this bracket? “I have always been interested in the “Perfect Wall” and building processes. I realized that many of the time consuming and expensive processes of air sealing and insulating are eliminated with the X-Bracket System with exterior spray foam. The X-Bracket System allows for the carpenter to nail on the brackets and furring strips and move on to the next job leaving the insulator to do what they do best. When I was building homes, there was never a day when I was excited to be an insulator,” said Scherrer.

By applying spray foam directly over solid tongue-and-groove boards, the InSoFast team claims to eliminate the need for house wrap, reduce material waste, and significantly improve airtightness—achieving beam-style construction at a pole barn price.They also declare that the X-Bracket system, continuous insulation simplifies electrical installations by keeping all wiring on the exterior and securing furring strips for various siding options.

The InSoFast team also indicates that the success of the insulation installation depends on the meticulous setup of the X-Brackets. The journey begins with confidently attaching the brackets to the sheathing using screws, nails, or adhesive. Then, securing the furring strips to the brackets thus creating a solid foundation for the siding or roof sheathing. When applying foam insulation, whether open or closed, embrace the 1/4-inch setback from the furring strips to promote cross-ventilation.

According to InSofast the 3/4-inch furring strips form a vertical gutter that facilitates drainage and drying, demonstrating the harmony of design and function. In the case of dense-pack insulation, a water-resistant barrier, like house wrap, gracefully stretches over the brackets, forming a cavity for the insulation. Furring strips stand as guardians of the house wrap, holding it firm as the insulation flows into place.

InSoFast highlight the X-Bracket’s Features

- Meets Passive House airtightness standards while effectively mitigating thermal bridging.

- Requires up to 40% less R-value to satisfy building codes.

- Enhances soundproofing, ensuring the pole barn is as quiet as a traditional home.

- Offers long-term durability with an integrated rain screen for effective moisture control.

- Increases the lifespan of the home and the siding and roofing materials by draining moisture from the wall assembly while promoting rapid drying through ventilation.

Professional Builder Matt Risinger’s take away

The SFMT first recognized Matt Risinger’s appreciation for the X-Bracket System during a trade show, where he proactively shared his thoughts on social media. With thirty years of experience in the construction industry and now in his 20th year as the owner of Risinger Build, Matt’s commitment to building science, quality workmanship, durability, efficiency, and comfort has earned him a substantial following. He is widely acknowledged as a building science expert and serves as the host of “The Build Show.” The website BuildShowNetwork.com showcases contributions from 14 other building experts, creating invaluable content for the construction community.

“Many individuals build without fully grasping how water, weather, and climate impact construction decisions, including insulation needs,” Matt points out. He attributes the popularity of his website to a well-rounded approach, stating, “We discuss spray foam and support its use, but we also address rock wool and batt. We understand that there is no one-size-fits-all solution.”

The X-Bracket comes in various sizes ranging from 2.5 inches to 9.5 inches.

Matt was first introduced to open-cell spray foam, which he acknowledges for its distinct benefits, but he also acknowledges the advantages of closed-cell foam. “Many people may not realize its additional benefits. Closed-cell foam provides a built-in vapor barrier, structural rigidity, and a high R-value.” Consequently, he primarily uses closed-cell foam for homes. Matt appreciates that both open and closed-cell foam can help create an air-conditioned envelope, and spraying foam at the roofline transforms the attic into a conditioned space, enhancing energy efficiency by minimizing air leakage and heat gain. “Closed-cell foam prevents moisture migration due to humidity,” Matt explains. “With open-cell foam, if you don’t apply enough and face high humidity in attics, you can encounter issues.”

Before the market introduction of the X-Bracket System, Matt spoke with its inventor and discovered numerous effective applications for it since then. He states, “It’s a perfect match for retrofitting, combining closed-cell foam with the X-Bracket, resulting in excellent opportunities to improve the performance of existing homes during exterior remodels. The X-Bracket allows for continuous exterior foam insulation without thermal bridging, significantly enhancing performance.”

Does the X-Bracket present a beneficial solution for builders and architects in their efforts to enhance installation efficiency and refine insulation plans and specifications? The Spray Foam Magazine team is eager to observe the performance of the X-Bracket on upcoming projects.

Spray Foam Magazine does not take editorial positions on particular issues; individual contributions to the magazine express the opinions of discrete authors unless explicitly labeled or otherwise stated. The inclusion of a particular piece in the magazine does not mean that individual staff members or editors concur with the editorial positions represented therein.

Disqus website name not provided.