Tanks for the Challenge

Spray Foam Magazine – Fall 2025 – Unlocking the potential to succeed in this industry takes training, persistence, ingenuity, and a dash of patience. However, even after mastering the art of spraying, other challenges can still hinder success. Having a business head, and the ability to pivot, plan, and pursue are key attributes. The team at Spray Foam Magazine caught up with one Canadian SPF business owner to explore how these skills have produced a thriving business that’s not tanked!

The journey began in 2011 when Lane Mizera and wife Stacey purchased their first rig while working on a personal project. At the time, Lane was employed in the coal industry, but after developing a passion for spray foam, he immersed himself in research, training, and ultimately built a successful SPF business. Within no time, he transitioned from his day job to running the business full-time. Lane and Stacey co-own and operate Total Site Services Ltd., a family-run business based in Alberta, Canada.

Fast forward fourteen years, and with their business thriving, Lane and his dedicated team recently completed a complex oil tank project that showcased their expertise to its fullest. They landed the project through a blasting and coating company. The two oil tanks, dating back to the 1970s, each have a capacity ranging from 67,000 to 80,000 barrels. However, the tanks' insulation and coating were in dire need of an upgrade due to issues with emissions and excessive venting. The company’s goal was to address the off-gassing promptly, preventing it from escalating into a major concern.

The oil company that owned the tanks preferred to use Canadian products, and after researching options, they decided on Genyk Polyurethane products. Genyk is a reputable spray foam and coating manufacturer, and since Total Site Services already uses their products, the referral was ideal for all parties involved. In addition to the foam, the tanks required a coating. Chosen for this project was a high-traffic coating available from SPI Coatings based in Kansas. SPI’s Super Therm coating is a flexible membrane that is ideal for this tank project due to its resistance to weather, condensation, mold, and mildew. Lane stated, “I believe this is, to date, the largest import of SPI’s Super Therm coating to Canada, with 775 U.S. gallons exported.”

Two inches of closed-cell foam was sprayed to cover the tanks' pins and then an additional two inches.

The tanks are in a remote area of northwest Canada, so Lane faced numerous logistical challenges. This planning took place five months before they were scheduled to be on-site. After calculating the necessary materials, Lane had to address the transportation of equipment since it was only accessible by air and flights to this remote area are limited to two or three a week.

For many contractors, this project would represent a logistical nightmare. However, Lane thrives on such challenges and, through past experiences, knows whom he can rely on. He arranged for Buffalo Air to transport all Total Site Services equipment. The crew flew with Canadian North Airways to the closest town to the tank location and rented a truck to transport their equipment to the site.

Due to the project's scale, Lane decided to use a Graco H-40 proportioner and a two-gun system, designed and built by Gord Maginnis Spray Products. After receiving specific cargo capacity details for the airplane, Lane recognized the remoteness of the location and chose to build a skid to accommodate the equipment. The team quickly constructed the skid, naming it “Optimus,” in just one week to meet the approaching deadline. Lane skillfully arranged all the necessary equipment on the platform, ensuring it could be easily transported by air and moved between locations once on-site. While Lane had previously built two skids for air transport across Canada, this project required a larger one to fit the bigger proportioner.

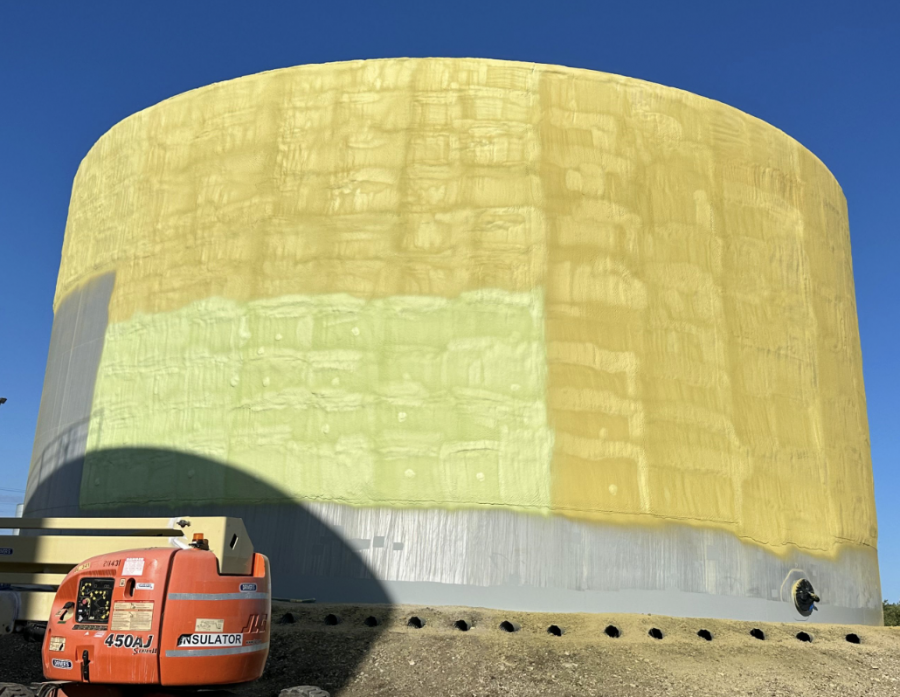

The tank during the different phases of foam application. Each square measured 8 ft tall by 6 ft. wide

Lane was particularly vigilant about safety protocols because medical assistance was a four-hour flight away. He confirmed that all necessary measures were in place before they even arrived on-site.

Total Site Services deployed a three-man crew for the spray foam application and a separate three-man safety crew due to the height of the tanks. The team was fully equipped with personal protective equipment (PPE), including supplied air and safety harnesses. The safety crew, specializing in rope access, ensured proper tie-offs and work restraints, allowing safe access to the tops of the 60-foot-tall oil tanks.

Upon arrival, Total Site Services found that the client had already prepared and cleaned the two tanks, which measured 120 feet in diameter and 60 feet in height. As a result, the crew only needed to perform basic masking to protect against overspray. However, the first tank presented a greater challenge due to the presence of pins from previously installed mechanical insulation that had been blown off by high winds. To address this, the crew sprayed two inches of Boreal Nature Elite closed-cell foam to cover the pins before applying an additional two inches.

The crew began spraying from the tops of the tanks and worked their way down. Since the tanks were live and active, there were occasional delays due to high-pressure alarms. If the pressure inside the tank rose too high, it would begin venting, requiring the crew to evacuate the area. They treated these alarms with caution to ensure no dangerous gasses were being released. Fortunately, after applying the first two inches of foam, the alarms did not sound, signaling that the foam was already improving the tanks’ performance.

Once the closed-cell foam was in place, the crew applied the SPI Super Therm coating, designed to block solar heat, using an airless paint sprayer. They applied a total of ten mils, using 155 pails to cover both tanks. Having visited the site beforehand, the Total Site Services crew anticipated potential wind issues. Since the tanks were actively in use, they couldn’t set up wind screens or fully encapsulate them. Lane communicated to the clients that while the finish might not be perfectly smooth, the primary focus was on the SPF and coating performance, rather than aesthetics. Despite these challenges, the crew achieved only a few minor visual deviations.

Lane's meticulous planning throughout the project also involved securing spare equipment parts, which proved to be invaluable when the start panel of one machine

malfunctioned. “I’d like to express my sincere gratitude to Mike Roberts at HMFT Inc for assisting us in acquiring all the necessary parts,” Lane notes. With a spare machine on hand, they were able to swiftly replace the damaged components.

The project took thirty days on-site: twenty days for foam application and ten days for coating. However, five months of preparation, including calculations, site visits, skid design, material ordering, and safety planning, set the stage for success.

The client was highly impressed with how the foam exceeded expectations by significantly reducing the tanks' emissions. The coating is expected to last for at least five years before reapplication is necessary, while the foam is designed to last throughout the tank's lifespan. Thanks to their outstanding planning and execution, the project was a success, adding another win to the Total Site Services team's track record.

Disqus website name not provided.