Second Time’s the Charm

Spray Foam Magazine – Late Summer 2025 – Oceanfront properties are dream home material; doubly so for multi-million-dollar homes on the scenic coast of Nova Scotia, Canada. But maintaining luxurious architecture requires precise construction and infallible materials from the start, lest it lead to a messy remodel years down the line. Beyond the aesthetic touches like paint colors, light fixtures, and flooring, it’s the unseen components behind the drywall that really make or break a home. Some homeowners find this out the hard way.

During an extensive roof remodel at an ultra-luxury home on the Halifax coast, peeling back the roofing layers revealed that the closed-cell spray foam previously installed to the roof deck had failed. This failure left the roof vulnerable, and meant the foam had to be completely excised before it could be reinstalled. It would then need to be shaved down evenly with precision tools– all with zero disruption to the home’s facade or the surrounding neighborhood. A project of this magnitude couldn’t go to just anyone, especially considering it was the roof’s second foam installation. So, the general contractor called on a spray foam company whose work they already knew and trusted: Trinity Energy Group. Having worked with Trinity Energy on a previous high-end residential project, the contractor knew this local team was the best in the business for demanding, detail-oriented jobs with little margin for error.

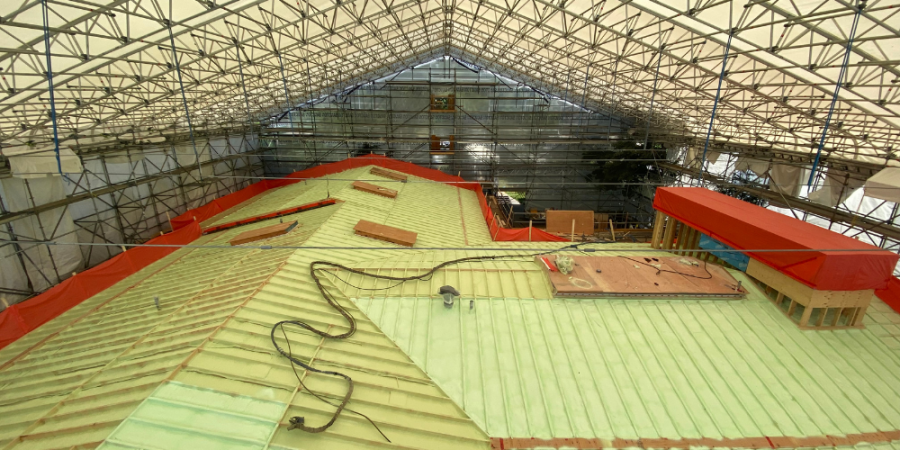

The team installed the red protective poly around the perimeter to catch overspray

Trinity Energy Group spent three weeks spraying closed-cell foam between the studs atop this Halifax home's clean yet humid roof deck

Over the course of three weeks in September 2024, Trinity Energy’s team of four installed six inches of closed-cell spray foam across the 6,000 square-foot roof, all while enclosed in full construction hoarding. The humid, tent-like conditions posed foam adherence challenges and spelled sweaty work for all involved. Still, the team persevered. Reinstalling the closed-cell foam layer remained the best all-in-one option for the roof.

“Spray foam was the ideal choice due to its superior R-value per inch, built-in vapor barrier, and added structural integrity.” said Kaitlyn Carvery, project manager for Trinity Energy. They were determined to see it through to the end, and show what a difference foam can make when it’s installed properly.

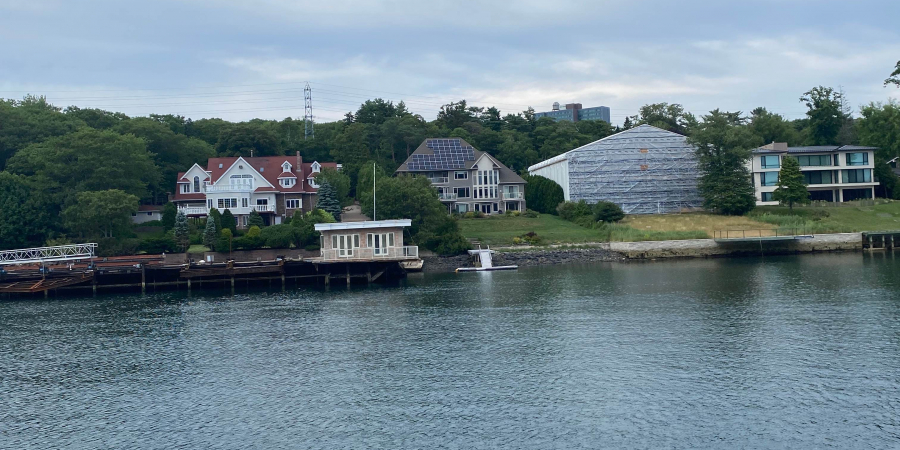

Pulling up to the house, the Trinity Energy team noticed it stood out among its other neighbors along the Halifax waterfront. Amid all the beautiful mansions with solar panels and private docks, this house was shrouded in plastic hoarding. Prior to the spray foam team’s arrival, the general contractor had already erected the hoarding, which consisted of tent-style poly material supported by scaffolding. It helped contain debris during the remodel, such as preventing the wind from catching overspray and depositing it on the neighboring homes and lawns. It would also keep the work area safe and dry from the unpredictable coastal weather. However, once they ascended to the roof, the team realized just how humid and stifling it was underneath the poly.

The plastic-covered house (on the right) was a peculiar sight compared to its other waterfront neighbors

“The tent enclosure created humidity challenges due to condensation forming on the interior surfaces,” Carvery explained, adding, “This was caused by fluctuating weather conditions outside, like heat and rain.”

Everything and everyone was sweating. Spray foam loves heat but moisture is a no-go, and at this rate, the foam would never cure. To do the job correctly without risking a repeat of the subpar install they were there to clean up, they’d need a few extra supplies. Twelve industrial-sized dehumidifiers plus a handful of commercial fans, to be exact.

The general contractor rented the equipment they’d need to keep the space dry. Getting the dehumidifiers and fans up and running made a palpable difference in the humidity levels beneath the hoarding, but the spray foam team still didn’t take any chances. Often, they started or finished their workdays in the evening when the humidity was lower. They also regularly tested the area’s humidity levels, and did not install any foam unless levels were below 80. While it may have felt tedious at the time, these precautions would make a world of difference in the foam’s final quality.

With the humidity levels sorted, the team started on their minimal amount of prep work. The general contractor had already removed the old foam and erected the hoarding prior to their arrival, so all Trinity Energy really had to do for site prep was install a rip-proof barrier around the inside of the perimeter to double up on the overspray protection. Exposed wood studs and planks created tripping hazards, so they also put down wood planks to walk on, and to further protect the numerous skylights from overspray.

The hoarded building meant less fresh air passing through the poly, so everyone on the roof, helpers included, wore masks of the highest caliber. The sprayers wore 3M FF-400 Series full face respirators complete with fresh air hook-ups, while the helpers wore 3M HF-800 half face respirators. Sprayers suited up in Tyvek coveralls and disposable gloves to protect their skin and clothes. After hanging the poly, placing the planks, and donning the PPE, it was time to fire up the H-40 and Reactor 2 XP2 reactors.

The Fusion FX gun affixed to each Reactor allowed for a smooth foam application across the roof deck. They installed six inches of closed-cell foam between studs in multiple passes, pausing occasionally to check quality.

“We conducted on-site density and adhesion tests to confirm proper adhesion and that the application met required standards,” said Carvery. Keeping the foam flat, smooth, and uniform would allow the general contractor to finish the remodel by installing the rest of the roof atop the foam.

Having a sizable crew meant work could keep rolling as long as humidity levels remained in check. After the foam fully cured, the helpers used a CI cutter to shave it down until it was flush with the studs.

The team sprayed and shaved the foam so smoothly, from a distance the roof almost resembles rows of delicate vanilla wafer cookies rather than hardy closed-cell foam

Precision tools like the CI Cutter can cut through closed-cell foam like butter without damaging the wooden studs, although they had to be careful about the amount of pressure applied to the shaver to prevent accidentally gouging the foam. Shaving the foam down left a smooth, flat, and uniform surface for the general contractor to install the rest of the roof over top.

"The shaving process is not particularly difficult. It's just messy. Foam shavings get everywhere," said Carvery. The crew used a STAR Vacuum to clean up the excess.

With the foam sprayed and shaved and the debris vacuumed up, the roof looked better than good. When viewed from the scaffolding above, the foam rows resembled not hardy construction materials, but giant rectangular vanilla wafer cookies laid back-to-back; delicate, smooth, and layered to perfection.

Trinity Energy Group's reputation is what landed them this ultra-luxury job, and their capable attitude is what helped them see it through the challenges. They recognized the small margin for error in the humid hoarding environment and refused to cut corners. For Trinity Energy, it doesn’t matter that the foam they painstakingly installed will be covered by wood and shingles. Unlike the failed foam job they came to fix, their obsession with precision created a hidden work of art sure to prolong the roof’s longevity for years to come. And the fact that no one is likely to see it again until decades later means they accomplished their goal.

Published by Spray Foam Magazine

SprayFoam / Spray Foam Insulation

Disqus website name not provided.