The Party Wall Solution for Homebuilders

Spray Foam Magazine – Fall 2025 – Today’s homebuilders face numerous challenges. Stricter building codes, difficulty sourcing land, a lack of skilled labor, and tariffs on building products are among them. Overall, construction costs are rising, and solutions are in demand.

“Enter the W-Wall Assembly, a fire-rated, load bearing partition wall for use between apartment, townhome and condominium units” says David Dietrich, National Residential Manager with Huntsman Building Solutions (HBS). “This assembly benefits from high-performing spray foam insulation, while reducing construction and labor costs.”

The Design

W-Wall is an all-in-one solution for two-hour fire rating, air sealing, and acoustic performance. It is assembled at the construction site by framers and/or spray foam contractors.

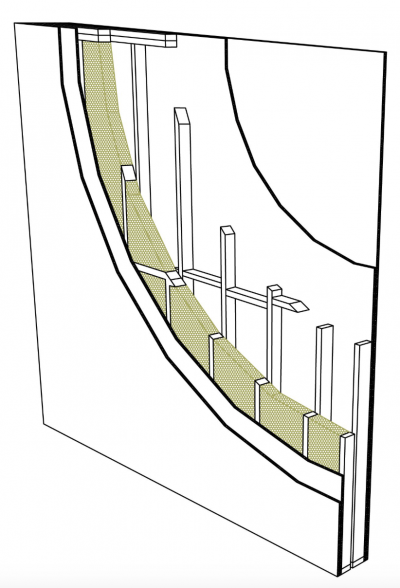

The assembly incorporates open-cell spray foam with a series of additional materials. These include wall sheathing consisting of two layers of 5/8 inch Type X gypsum wallboard on each side of the assembly (only the face layer gypsum needs to be plastered); walls constructed with 2x4 studs at 16 inches on-center (no need for eight inch off-set); sheathing secured with screws; and the finished layer covered with tape and joint compound. One side of the wall leaf is filled with three and a half inches of Huntsman Building Solutions open-cell spray foam insulation and there’s a minimum one-inch air gap between the two wall leafs. The assembly is one-inch thinner than the typical shaft wall, providing greater interior square footage.

Huntsman Building Solutions open-cell spray foam insulation systems are approved for use with W-Wall. All other materials in the assembly are commonly sourced; no specialty materials are required. Any brand of 5/8 inch Type X gypsum (paper-faced or glass-faced), drywall screws, tape and joint compound, and typical stud framing members may be used. Electrical can be run inside W-Wall but must follow IRC requirements.

“W-Wall was designed with builders and architects in mind,” adds Dietrich. “Both are looking for high-performing construction solutions that save money.”

Diagram of W-Wall Assembly with spray foam application and location shown in light green.

Educating Builders on W-Wall Benefits

Spray foam contractors are in the unique position to counsel builders on, as well as install, construction solutions that leverage spray foam and its benefits. W-Wall is one such solution. It addresses some of the key cost and labor worries builders face. Using W-Wall in a residential construction project saves up to three days in cycle time for townhomes, and potentially more for apartments and condos.

As important as the materials in the assembly are, so too are those not included. Costs are lowered for builders as materials typical to party walls – shaft liner panels, fiberglass insulation, and the caulk and seal package – are absent in W-Wall.

“Compared to other partition wall systems, W-Wall is fast and easy to install,” says Dietrich. “It reduces labor needs, specialty materials, and costs and is a win for residential builders.”

Contractors can also inform builders of the assembly’s air sealing capabilities and acoustical performance. Energy efficiency and airtightness are optimized, helping with blower door issues. Also, due to open-cell’s unique characteristics, W-Wall provides soundproofing benefits, which will last for the life of the structure as the spray foam will never sag unlike traditional insulation. Residents who live on either side of the wall will enjoy not hearing the noise their neighbors make.

HBS’s products have also demonstrated a lower embodied carbon compared to other types of insulation. Additionally, spray foam helps save on operational carbon emissions, increasing its advantage over other products. Finally, because spray foam can replace many materials while achieving the same or better performance, environmental impact is lessened.

W-Wall is fire rated for two hours, passing ASTM E119 in accordance with IBC requirements, making it the first spray foam wall assembly of its kind to pass. Additional certifications include ASTM E119 for Two-Hour Load Bearing Assemblies, ASTM E90-STC 57 for Sound Transmission (the minimum code requirement is 50), ASTM E2178 for Air Permeance, ESL 1373 - ICC Evaluation Service Listing, and TER 2011-01 – Technical Evaluation Report. W-Wall is also (depending on the installed products) Greenguard Gold certified, indicating low VOC emission and ensuring better indoor air quality.

Huntsman Building Solutions provides technical support to contractors, builders and architects using the W-Wall Assembly. A technical evaluation report is available for all

50 states within the U.S., evaluating the assembly’s performance, demonstrating its compliance with building code, and supporting building product and system approvals. A complete set of W-Wall Assembly drawings is available upon request. The Huntsman Building Solutions team is also available to review design details and specifications, provide onsite quality control, help tailor the W-Wall system to the specific project needs, and to ensure quality installation.

Maxime Duzyk is senior global director, building science and engineering at Huntsman Building Solutions

Direct any questions about the products mentioned in this article to Huntsman Building Solutions at www.huntsmanbuildingsolutions.com

Spray Foam Magazine does not take editorial positions on particular issues; individual contributions to the magazine express the opinions of discrete authors unless explicitly labeled or otherwise stated. The inclusion of a particular piece in the magazine does not mean that individual staff members or editors concur with the editorial positions represented therein.

Disqus website name not provided.