Nothing to Sphere

SPRAY FOAM MAGAZINE – The impressive column-free interior bowled roof, otherwise known as the MSG Sphere, dominates the horizon on the Las Vegas Strip. Weighing just over 13,000 tons, the mighty steel framed, dome-shaped roof trusses were welded and bolted together, which also presented the challenge of ensuring it was all watertight. What kind of roofing company could deal with such a vast and unusual shaped roofing system; an iconic project that has never been completed before? The Spray Foam Magazine team (SFMT) spoke with Commercial Roofers, Inc., the Las Vegas roofing contractor who enthusiastically accepted this roofing and waterproofing endeavor to find out more.

Built by Madison Square Garden Entertainment Corporation, the inside of the Sphere measures 1,200 ft. (about 365.76 m) and the outside of the tension ring 1,400 ft. (about the height of the Empire State Building). Scheduled to open in the Fall of 2023, the enormous Sphere is an astounding 366 ft. high and 516 ft. wide and will offer visitors spectacles, such as live sporting events, music, and other monumental events. The 16K LED screens will engulf the audience and the haptic seats (a seat that provides sensations to an occupant) will make the visitors automatically feel absorbed into the surroundings.

The immersive sound has 164,000 speakers and beam-forming technology and audio, so the audiences will not only hear and see performances, but feel like they are part of the action too. There will be seating for 18,000 people, including 23 suites, and it will be connected to the Venetian Expo by an indoor pedestrian bridge. Already labeled as the largest Sphere on earth, something this impressive needs a grand roofing system.

Scott Howard, Dennis Perry, and Dennis Conway launched Commercial Roofers, Inc. 25 years ago. Howard was a third-generation roofing contractor whose family business, Howard Roofing, started in the Las Vegas Valley in 1959. In 1986, his family sold the business where he held the role of project manager. After the sale, he became manager of the Las Vegas office, and by November 1996, Scott and Janet Howard and Dennis and Linda Conway purchased and renamed the company Commercial Roofers Inc., returning the business to local ownership.

Dennis Conway has been in the construction industry for 38 years, and in 1983 he became president of Honolulu Roofing, the largest roofing contractor in the South Pacific. In 1995, he moved to Las Vegas to partner with Howard. However, in both 2019 and 2020, significant changes occurred with the ownership of Commercial Roofers, Inc. Scott and Janet Howard became the sole owners of the company while Scott Howard remained President & CEO.

The hardworking crew on the Sphere project, from left to right: Fernando Lozada, Curtis Perry, Nibrado Landeros, Emiliano Perez, Silverio Valdera, Armando Landeros, Milton Uribe, Gregorio Jimenez, Edgar Ramirez, Jose Vega, Leopolvda Seville, George Moses, Abdon Luna Sandoval, Johnny Humphries, Cody Jamison, Charlie Sadahiro, Andrew Orozco, Salvador Bravo

Soon after the Howards took ownership of the company, tragedy struck. Owner, leader, mentor, and friend, Mr. William “Scott” Howard passed away. His wife, Janet Howard, assumed her current position of President and CEO, saying, “Prior to my husband passing, he put together an amazing team, who I personally work with. These are families whose hearts are for our company; they really are an exciting extension of our family. I also have my children Sean and Lindsey at the company, and between the two of them they have 30 years of this business’s knowledge.” Janet Howard is well-loved and regarded in the industry and has recently received her Women Business Enterprise certification status (WBE).

Commercial Roofers are proud to embrace their employees as extended family. With strong morals, special warmth, and job security being a fundamental philosophy throughout their business. There are currently 30 families working within Commercial Roofers, including mothers, daughters, fathers, sons, brothers, and even grandfathers. Everyone at Commercial Roofers shares the main objective of respecting one another, having each project completed on time, within budget, and with little to no problems.

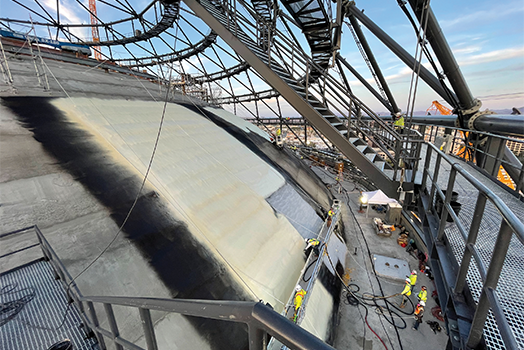

The crew is applying foam and coating from one of the many motorized articulating 40-ft swing stage with oversize balloon tires to protect the foam, while moving up and down, applying the coating.

Scott Howard knew he wanted Commercial Roofers to be involved in the cutting-edge Sphere project, but passed away before it was completed. He also knew that there were not many, if any, other companies in the country that could complete a project of this scale. So, the team decided that Commercial Roofers would value re-engineering this project. Dennis Perry, a senior project manager at Commercial Roofers, thought the original plan of a single ply PVC roof with an R-30 insulation board anchored down to the concrete deck, would not work.

Dennis Perry discussed the options with the team and they all acknowledged that having to put 65 semi loads of insulation up on the Sphere and having it laid out was a big logistical problem due to the debris and the schedule. They knew that having a spray foam roofing system with a coating overtop would eliminate the material loading issue and avoid the 20-25 percent waste that would have occurred trying to install PVC on the round Sphere.

When the time came for the general contractor to ask Commercial Roofers for their professional opinion on the roofing system, they replied, “A spray polyurethane foam roofing system would work.” The research and engineering Commercial Roofers presented impressed Madison Square Garden, and they in turn, were awarded the project.

General Coatings Manufacturing Corp. is known for their quality SPF and roof coating products and their outstanding customer service. General Coatings representative, Steve Goold, said, “With the ongoing material shortage at the time, we were able to assure Dennis Perry of Commercial Roofers that we could deliver a quality product on time with technical support. We have been working together ever since.”

General Coatings even created a special formulation for the top coating. The coating developed was a slate gray color that would allow visitors to look at the LED monitors and not see the roof behind it, making it appear as if the roof had vanished.

The crew arrived at the location with three portable PMC PH 40 rigs. Commercial Roofers make it a priority to ensure their employees are always confident and safe on a job. With their morning safety meeting, they guaranteed the team was ready for another safe day using the correct PPE, including hard hats, respiratory equipment, gloves, suits, and fall protection. The crew also required proper lighting because many of the shifts took place at night. Coordinating schedules with the iron workers, who were building the exoskeleton of the Sphere was crucial. They were working at the same time that the roofing system was being installed, which required several shift changes.

Having a motorized swing stage for the job was also imperative, as it needed to go up and down the very steep exterior aspects of the dome. With Leading Edge Scaffold providing the thirty-two swing stage platform carriages for the project, it was like a well-choreographed dance. There were five scaffolding stages going at one time, allowing three spray foam applicators to work simultaneously. The project managers approached the Sphere project as if dividing a pie into pieces, spraying one slice at a time. For example, if a part of the pie was sprayed, then the crew would move over to the next section and then return to the previous section to spray the joining area.

The Commercial Roofers crew installed five inches of General Coatings Ultra-Thane 230 spray foam. Following the application of this two-component closed-cell foam, an additional crew followed behind to apply the Ultra-Flex 1000 elastomeric basecoat and topcoat at five gallons per square foot to finish at 40 dry mils.

While being tied off and scaling the ball, the crew was able to apply coating.

Once the circumference of the dome was completed, crews moved to the top of the dome, where they were able to stand while being tied off in case of a fall.

At the bottom of the Sphere is a wide tension ring. The SPF needed to be applied in a way to create a positive water flow to the drains within the valley, the high points, the crickets, and the tapers all being important. To apply the SPF in such a way takes both precision, technique, and pre-planning, in addition to being mindful of overspray. General Coatings provided support during the installation by positioning their technical team on site to observe and answer any questions when needed.

Commercial Roofers were confident that their experienced crews would be able to handle a spray foam installation of this magnitude, but as an added measure, they sent them for three days of additional training at Intech Equipment in Southern California.

Commercial Roofers even switched out the wheels of the swing stage, which were too small and were pressing the foam. They used their engineering skills to fabricate a bracket to help fit larger wheels so when the swing stage went up and down, it did not damage any of the material.

The logistics involved in this project were immense. Commercial Roofers can take on such demanding projects as they are adamant in their belief that, “You are only as good as the people you surround yourself with.” Their team, whose camaraderie and dedication coupled with a high-quality manufacturer like General Coatings, have made this iconic Sphere a well-rounded project. The client is extremely happy with the result, and just like the MSG Sphere, companies such as Commercial Roofing will always shine brightly making their presence known and respected for years to come.

For use by SprayFoamMagazine.com & Spray Foam Magazine

Disqus website name not provided.