Foam in the Frozen Frontier

Spray Foam Magazine – Late Summer 2025 – Cape Newenham, which sits on the southwestern coast of Alaska, is a little-known place to most. With no town or residences nearby, the location is home only to a long-range radar station. This facility fulfills an important role in the country’s defense and the integrity of its physical structure is critically important.

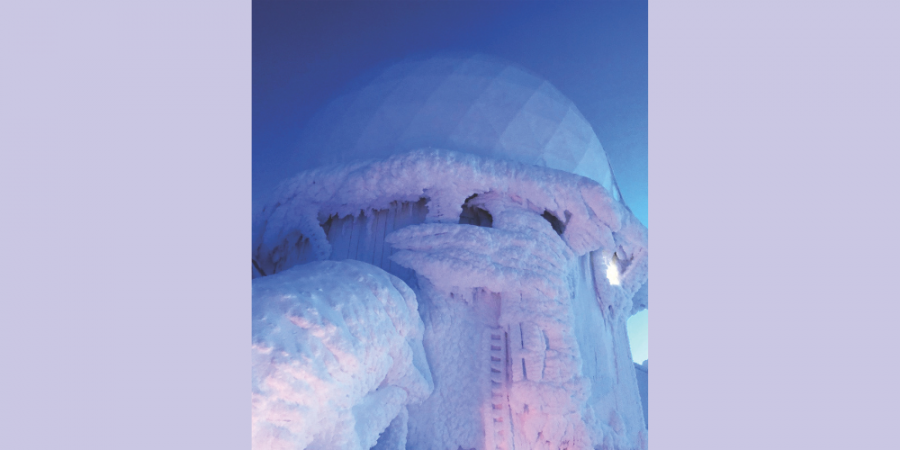

View up to the radar station dome on a clear day in Cape Newenham, AK.

The station sits within a subarctic region with long, extremely cold winters. The weather is intensified by the maritime influences of the Bering Sea. Summers are cool and short in length. There is no established road system, and everything needed for station maintenance, including personnel, must be flown in via a simplistic landing strip.

Originally insulated with fiberglass batting, the material failed in holding up to the extreme temperatures, vapor drive, and winds of Alaska’s western coastline. Over time, moisture had intruded gaps in the structure’s assembly, resulting in rot and an under-performing and inefficient building envelope. It had become abundantly clear the structure needed to be opened to facilitate the removal of fiberglass and rot, and ultimately, re-insulated with a higher performing material.

No newcomer to projects with uniquely challenging parameters like this, Palmer, Alaska-based Polyseal Insulation was recruited for this project through an existing relationship with Arctec Alaska, a general contractor specializing in government contract work.

“Our team has sprayed military radar domes and barracks facilities in remote regions of Alaska for Arctec and its customers in the past,” says Paul Broderson, co-owner and partner of Polyseal Insulation. “We were very happy to be called on for this one.”

Visually, the tower structure resembles a faceted dome. With twelve sides, it measures approximately 50 feet in diameter with a 25-foot height to the radar deck. Polyseal brought in a two-man crew—installers Sam Wirtanen and Jacob Lee—to complete the project. But first, there were several logistics to take care of due to the remote nature of Cape Newenham. This included navigating how to get materials and equipment to the site.

Polyseal bundled, shrink wrapped, and palletized its equipment and spray gun, preparing all items to be flown in. A Conex shipping container would act as a makeshift rig for the crew onsite. Luckily, one had previously been transported in on a barge and was available for use. Once all materials and equipment reached the destination via plane, they were placed inside a heated storage space near the landing strip. With the radar station up on a hill above, a front loader was used to transport everything up to it for the SPF installation. Some items were brought up the hill via an underground transport tunnel.

“I can’t stress enough how thorough and precise we have to be in planning to get all our materials to a site like this,” says Broderson. “We’ve gotten good at planning for all contingencies, since there is no feasible way to get a missing item there once we are on the job.”

Polyseal had selected Huntsman Building Solutions’ Heatlok HFO Pro, a high-performance closed-cell SPF, for this project.

Using front loader to transport SPF drums up to the station for installation.

“We have experience with a handful of closed-cell spray foam systems. In this instance, Arctec asked us to vet and choose the foam to be used. Because we really like the quality, consistency and sprayability of Heatlok, we recommended it to Arctec,” says Broderson.

Polyseal notes the exceptional service the Hunstman Building Solutions team provided. “Because of site and customer variables, there were limited times we could fly the Heatlok foam sets in,” he says. “We also had to make sure to install the foam before the shelf life of the B-side material had lapsed. The Huntsman team was incredibly helpful in helping us navigate all these parameters.”

Polyseal Insulation’s installers on the project, Sam Wirtanen (left) and Jacob Lee (right).

Working during the region’s short summer window, the two-man Polyseal crew sprayed the Heatlok HFO Pro, in 10-inch thickness, to the wall cavity of the tower’s exterior walls. They also applied it inside the tower’s crawlspace as well as to all confined space sections to achieve a total R-70 value.

“Sam and Jacob were able to seal off all the studs and structural members, leaving no air gaps in the tower’s envelope,” says Broderson. “Once the foam application was complete, DC-315 intumescent paint was applied over all the exposed foam in the crawl space.”

Luckily the weather during this project posed no problems. “Sam and Jacob were able to complete the project within 12 working days, avoiding any weather issues,” adds Broderson. “During the project duration, they both slept onsite in camp lodging.”

The Polyseal team’s work done on this project was recognized earlier this year with a 2025 SPFA Industry Excellence Award.

“This radar station is a prime case study on why quality closed-cell spray foam is always the right and only insulation choice for structures located in frigid climate zones,” says Broderson. “There really is no other insulation option that will do the job like spray foam will.”

Published by Spray Foam Magazine

SprayFoam / Spray Foam Insulation

Disqus website name not provided.