Moisture Strikes Again

Spray Foam Magazine – If you have been in the spray foam business for any length of time, you already know that isocyanate can crystallize creating a lot of problems. What you may not know is that the crystallization is not caused by exposure to air, but rather by exposure to the humidity that is in the air. When spraying foam, you are drawing isocyanate out of the drum. That liquid must be replaced by air, otherwise you will create a vacuum inside the drum and make it collapse. We need to let air in, but not the humidity.

To do that, we use a desiccant dryer. It’s a canister that threads into the small hole on the top of the A side drum. As air goes through the canister, the desiccant inside absorbs the moisture. The dry air doesn’t react with the isocyanate, preventing that dreaded crystallization. The desiccant dryer has a visual indicator on it that turns from blue to pink when it’s used up, so you’ll know it’s time to change it out. With less crystallization, your screens won’t load up as fast, your pump seals will last longer, and you’ll have less downtime. Just FYI, these desiccant dryers are not needed on the resin side drum.

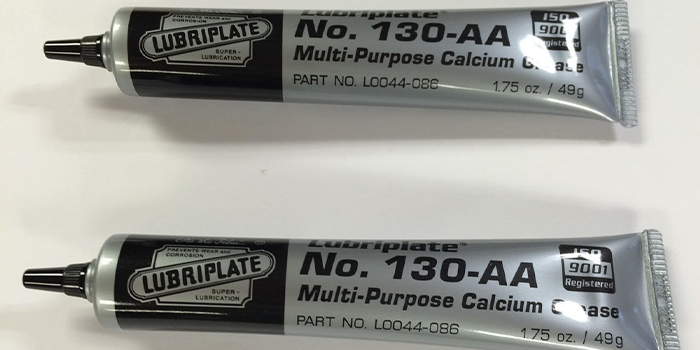

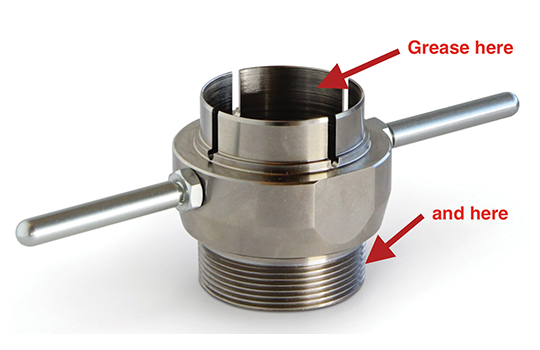

Let’s also talk about what Isocyanate is going to do to your transfer pump. No matter how hard you try not to, you are going to get isocyanate on the threads of the pump. That isocyanate is going to crystallize and glue the threads on the transfer pump to the threads on the drum. To avoid this, apply grease to the threads each time you move the pump from one drum to another. You’ll also want to occasionally apply grease between the pump collar and the pump itself so that the pump doesn’t become glued to the collar. Every few months, it’s best to remove the collar from the pump, and clean it up with a wire brush, put a fresh coat of grease on the threads and the inside of the collar, and put it back on the pump. This only needs to be done on the isocyanate side. The resin side does not react with humidity, so it won’t lock up like the isocyanate side.

For use by SprayFoamMagazine.com & Spray Foam Magazine

Disqus website name not provided.