From Historic Landmark to Modern Marvel

Spray Foam Magazine – Late Summer 2025 – The Galt House Hotel in Louisville, Kentucky, has long been woven into the fabric of American history. Originally built in 1835 as the home of renowned physician and botanist Dr. W.C. Galt, the hotel quickly became a central hub during the Civil War. In 1862, Union General William “Bull” Nelson, a Kentucky native, used the hotel as his base of operations. Tragedy struck on January 11, 1865, when a devastating fire left the hotel in ruins. But by November 1869, a new Galt House, designed by architect Henry Whitestone, rose a block away at 1st and Main Street.

So, what does this storied past have to do with spray polyurethane foam? That’s exactly what the Spray Foam Magazine set out to discover.

In April 2018, the Galt House Hotel underwent a sweeping renovation that modernized its interiors—from refreshed guest rooms and revamped lobbies to updated event spaces and four reimagined restaurants and bars. Yet, one critical component remained untouched: the 30-year-old Spray-Tec Inc. roof. Having outlasted its expected lifespan by an impressive 10 years, the roof finally showed signs of fatigue. The 2018 renovations had subjected it to significant foot traffic and heavy equipment loads, especially during HVAC installations. Although it had only two minor leaks, it was time to give the roof the attention it deserved.

After complete tear off of old roof assembly, Spray-Tec added 3-in. Iso board followed by 1/2 in. Primed dens deck, and then capped the entire assembly with an inch and a half of Spray Foam, two coats of silicone and a layer of ceramic granules.

Enter Spray-Tec Inc., a Shelbyville, KY-based leader in commercial roofing, insulation, and waterproofing. Collaborating with the hotel’s Director of Engineering, they meticulously planned a full roof replacement for completion by summer 2024. Spray-Tec arrived onsite with a robust setup: a PMC PH-55 rig with a Graco heated hose, a Hennes-Johnson sprayer, and a dual-hopper hybrid granule blower system, everything needed for a top-tier roofing job.

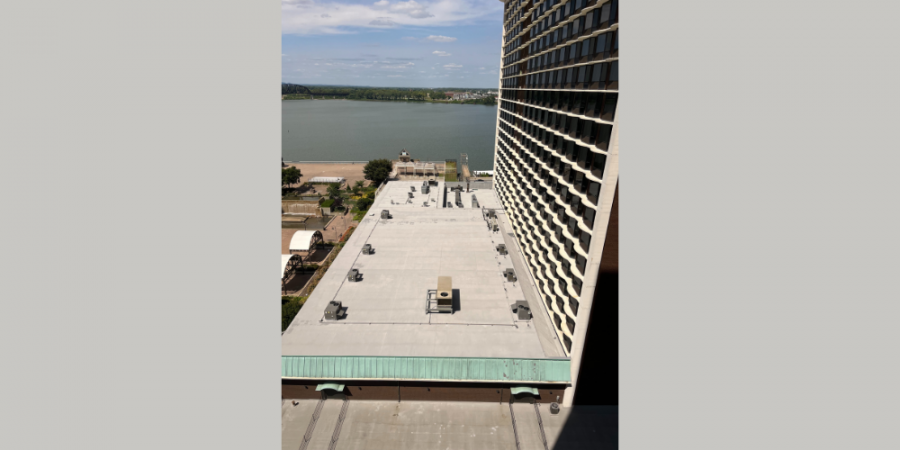

The project took place on the hotel’s third floor, with roof access requiring special permissions. The team used The Belvedere, an elevated event plaza west of the hotel overlooking the Ohio River, as a staging area. However, strict weight limitations meant the crew had to fully unload their trucks and trailers before use.

To maintain safety, they also installed a temporary fence around the staging site.

Spray-Tec partnered with Brand Safway to erect scaffolding, creating a secure work platform and a designated path for disposing of roofing debris. A crew of six, including crew leader Mariano Perez, assistant leader Santos Herrera, and technicians Erik, Miguel, Pedro, Edvin, and Onilson, was assembled for the job. With comprehensive PPE in place (fall protection, safety flags, and a dedicated dumpster), the team began the tear-off. They stripped the roof section by section down to the tectum deck, including the perimeter edge metal and coping caps.

A unique challenge soon arose: the hotel’s busiest conference room was located directly beneath the jobsite. To minimize disruption, the tear-off was limited to 7 AM to 11 AM daily for a week. Using buggies, the crew carefully transported debris across the scaffolding platform to the dumpster, harnessed in and ever-cautious of guests and staff below.

With the old roof removed, the team shifted to installation. First came the mechanically fastened wood nailers, foam stop edge metal, and coping caps. Over this, they applied tapered isoboard and dens deck to create a solid base for 1.5 inches of Gaco’s closed-cell 2733 Roof Foam. Spray-Tec successfully covered 30,780 sq. ft. despite losing one day to high riverfront winds.

Before view of the lowest elevation over the kitchen area. This roof presented challenges due to all of the roof penetrations and ductwork to work around.

Shows completed roof section over conference rooms, meeting rooms and kitchen area of Galt House Hotel downtown Louisville.

Next, the crew sprayed Gaco S2022 light gray high-solids silicone as a base coat, followed by a topcoat. Into this wet top layer, they broadcast ceramic 3M granules using their dual-hopper system. All sheet metal work was completed onsite, and the crew meticulously sealed perimeter edges, flashings, coping caps, and scuppers using Dow caulk and v-grooving techniques.

After three weeks of disciplined labor, the crew wrapped up with touch-ups and a final warranty inspection. What’s most impressive is that they completed the renovation with minimal disruption to hotel operations. Thanks to the low-impact nature of spray foam systems, the crew was virtually invisible to hotel guests after the tear-off phase—an advantage conventional systems simply can’t match.

Today, the Galt House Hotel boasts a fully restored, high-performance Spray-Tec roofing system, backed by a fresh 15-year warranty and ready to weather the next chapter in its historic journey.

Published by Spray Foam Magazine

SprayFoam / Spray Foam Insulation

Disqus website name not provided.