Infrared Thermal Cameras Help Foam Contractors and Home Owners to Save Energy

Infrared Thermal Cameras Help Foam Contractors and Home Owners to Save Energy

ACToolSupply.com shows us “real life” examples of how a thermal scan finds the energy or structural problems in residential, commercial and industrial building.

By pinpointing problem areas, repairs can be localized, often saving your customers thousands of dollars in unnecessary work.

Feb 27, 2009 – Infrared thermal cameras, like the Fluke TiR1, Fluke TiR, FLIR B40, FLIR B50, FLIR B60, FLIR B200 and FLIR B250, will locate breezy areas, poorly insulated windows, doors, walls, ceilings, roofs, and electrical outlets that are allowing hot or cool air (and money) to escape. By pinpointing problem areas, repairs can be localized, often saving your customers thousands of dollars in unnecessary work.

When it comes to pinpointing costly energy loss in your home, thermography is the ultimate non-evasive diagnostics tool. Thermography is a technique in which infrared thermal imaging cameras, and often blower door systems, are used to photograph and measure temperature variations in residential, commercial, or industrial buildings.

All materials on earth emit heat energy in a portion of the energy spectrum, but the human eye cannot see this energy. A thermal imager / infrared camera can not only record this heat energy, but can also accurately measure the temperature variations of building materials.

These variations could indicate problems in the building’s thermal envelope, electrical, mechanical, plumbing, and water-proofing and insulation systems.

With today’s rising energy costs, it is important to show your customer where their money is actually going. Most people don’t realize that energy escapes homes and structures quite frequently through doors, windows, or poorly insulated areas. For the most part, these areas aren’t easily seen because they are covered by finished materials.

This makes it nearly impossible to target areas that may be affecting your customer’s energy bill. However, recent technology improvements have made is possible to target and repair these areas. Recent improvements in the availability, price, and size of hand held quality assurance tools and performance measurement devices have developed an affordable selection of tools that today’s modern and high performance insulation andbuilding contractor should not be without.

Now you can perform a thermal scan using an infrared camera instantly that will pinpoint energy related problems caused by poor workmanship, lack of insulation or material failure.

With the costs of energy increasing, thermal imaging is a worthwhile investment to the building owner when you consider how much more money your customers can save on their energy bills, and gain possible access to government and utility company incentive programs.

How easy it is to diagnose thermal envelope flaws, and referral business from your customers? Let’s take a look.

BENEFITS OF THERMAL IMAGING

- Locate areas where the house is not properly insulated

- Find cold spots in the house and locate uncomfortable areas

- Detect energy loss due to leaky windows and drafts.

- Reduce overall heating and cooling costs with home heat and AC loss surveys

- Doesn’t require building disassembly

- Conclusive and unbiased

- Easily demonstrate IR and generate reports for your customers

- Customers remember infrared inspections, in turn adding to valuable future opportunities based on the “word of mouth” promotional results.

Figure 1. The Window’s Ghost

|

|

This figure shows digital and infrared images of a home office. The homeowner complained about his office feeling cold and uncomfortable in the winter time. A visual inspection of the wall from the outside revealed a window that was bricked in. This image, taken with a FLIR B60, shows that when the existing window was removed and the opening was closed in, there was no insulation installed, causing the homeowner’s heating problems.

Figure 2.

|

|

This figure shows a digital and infrared image of a bedroom. The homeowner noticed that this bedroom was colder than any of the other rooms in the house. The infrared image indicated that missing insulation in the ceiling was the cause. Further investigation concluded that too much ventilation in the soffit caused the insulation to shift.

Figure 3.

|

|

This figure shows a digital and an infrared image of an attic access point inside a closet. In this case, the homeowner complained about the closet being cold in the winter. The IR image shows that missing insulation on top of the attic access was causing heat-loss inside the closet.

Figure 4.

|

|

Here is a digital and infrared image of the ceiling in a bedroom closet. This homeowner also complained about the closet being cold in the winter. The infrared image shows a framed in and un-insulated attic access that was dry walled over and then forgotten by the contractor.

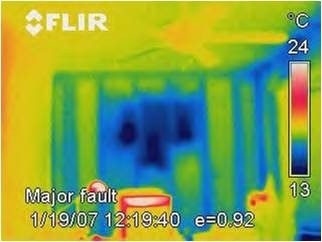

Figure 5.

|

|

This one shows a digital and infrared image of the underside of a floor from the basement. The homeowner complained about drafts along the sill-plate in his basement. He had used DIY foam insulation to fill all cavities and caulking along the floorboards, but still had drafts. The IR image shows air leaks along the T&G of the floorboards, which needed to be sealed.

Figure 6.

|

|

Here we have a digital and infrared image of a bulkhead above the kitchen sink. The homeowner could feel a draft, and he thought his kitchen window was leaking but wasn’t sure where. The infrared image shows that the draft didn’t come from the window but from the pot-light above it.

Figure 7.

|

|

This figure shows a digital and infrared image of a unique kitchen ceiling. The homeowner complained about drafts in his kitchen, but she needed help locating them. The infrared image shows cold air entering through the soffit and into the space behind the crown molding of the tin ceiling.

This article was contributed by AC Tool Supply. ACToolSupply.com carries six complete lines of thermal imaging cameras and imagers. They also offer complete resources and training on all thermal imaging devices.

Manufactures include; Fluke, FLIR, Ideal, MSA, Electrophysics. Your one stop infrared shop.

ACToolSupply.com

Phone: 877-207-1244

Disqus website name not provided.