Carbon and the Four-Letter Word

Spray Foam Magazine – Fall 2025 – In the past three months, I’ve managed to attend three national building conferences and a building science symposium. One invite led to another, and before I knew it, I was knee-deep in conversations about carbon, climate, construction, and everyone’s favorite topic…foam. Somewhere between hotel breakfasts and night caps with architects, a few insights stuck with me.

The Circular Economy Summit in Montreal focused on reducing carbon from construction waste, reusing materials, and cutting landfill contributions. Great ideas, until you’re trying to build with recycled drywall in February, when Montreal is in a deep freeze.

In Ottawa, the Passive House Conference was all about airtight envelopes and low-energy buildings. Insulation was a hot topic, and foam had few friends in the crowd. But the message was clear: carbon isn’t just an architect’s concern. It’s showing up in codes, specs, RFPs, and even with building owners. I recently received an email from the Canadian Board for Harmonized Construction Codes asking for feedback on embodied carbon in the National Model Codes. That’s a clear signal carbon isn’t just a design trend, it’s heading for policy.

After that, I wrapped up in St. John’s, Newfoundland for the CSC National Conference, complete with lobster, strong drinks, and a Screech-In ceremony I won’t soon forget. Somewhere in there, I asked architects and specifiers the big question: “Are you selecting materials based on embodied carbon?” The answer, in true Newfoundland style: “Lard Tunderin’ Jesus, YES.” If you haven’t been, it’s like Boston, but with weirder accents. They’re not waiting for the codes to change. They’re already baking carbon into material decisions, and not just for look how green I am LEED projects, but for everyday construction.

In Boston, at the building science symposium, the scene felt familiar: scotch, cigars, and carbon. If designers are moving toward carbon decisions, contractors won’t be far behind.

The ‘40% Elephant’ in the Room

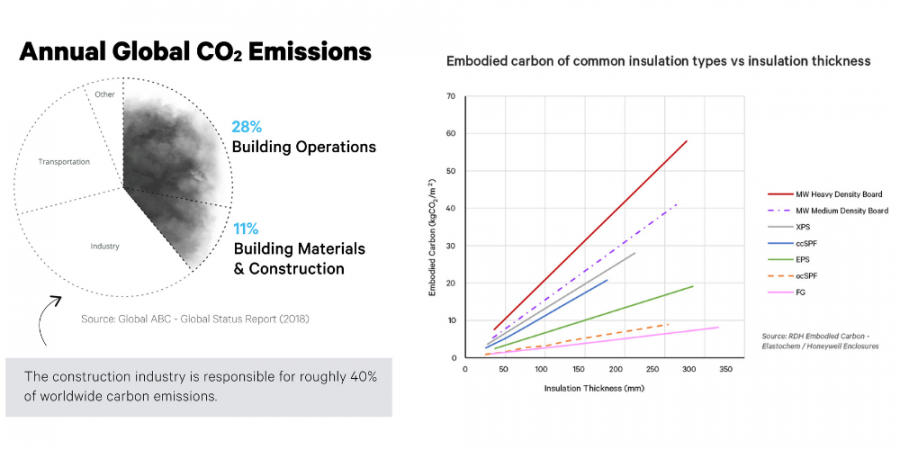

Construction is responsible for about 40% of global carbon emissions: 11% from producing and assembling materials (embodied carbon), and 28% from operating buildings. Insulation affects both. A high-carbon material front-loads emissions before the lights even turn on. Pick the wrong R-value or install poorly, and you’ll waste energy, and generate carbon, every day.

After two decades in this industry (which, for context, is about a third of the time since the Leafs won the Stanley Cup), I’ve seen insulation evolve from melting rock in energy-intensive furnaces, to chemical foams made on-site. Some products just handle thermal. Others, like ccSPF, tackle thermal, air, vapor, and moisture in one application.

Beyond R-Value: The Carbon Behind the Wall

Environmental Product Declarations (EPDs) are like carbon resumes for building products, detailing CO₂ impact from raw material extraction to disposal. EPDs, which are based on LCAs, give a baseline for carbon but not the full picture. LCAs provide information for calculations, but only EPDs allow product-to-product comparisons.

Here’s the catch: EPDs usually cover the material, not the system. They don’t show how insulation works with membranes, framing, or cladding, or how one product might replace several others. That’s why we need to assess full assemblies, not just components. Fortunately, new tools are helping make that easier.

Mineral Wool vs. Spray Foam: Same R, Different Game

Take a split-wall with four inches of ccSPF outside and four inches of mineral wool inside. Since mineral wool is vapor permeable, you’d also need an interior smart membrane. Swap in ccSPF inside, and you eliminate that extra layer.

The embodied carbon? Around 11 kgCO₂/m² for ccSPF versus 28 kgCO₂/m² for the mineral wool, about two and a half times higher.

With ccSPF, you get all four control layers in one. That’s why we should measure the whole enclosure’s footprint, not just the R-value. I’ll bet spray foam wins the embodied carbon battle for years to come.

A New Tool Worth Using

A new guide from RDH Building Science, Toronto Metropolitan University, and The Atmospheric Fund—New Design Resources for Embodied Carbon Targets—analyzes 26 real-world assemblies, showing the embodied carbon of each part: foam, cladding, framing, and more. It’s not just another whitepaper—it’s actually useful.

In late 2025, Elastochem and Honeywell will release additional wall assemblies comparing spray foam with other insulation types, another step in showing foam’s carbon advantage.

That’s not to say mineral wool is bad. It’s fire resistant, durable, and performs well. But its density means higher embodied carbon per inch. Operational savings may offset that over time, but spray foam’s higher R-value and air sealing offer a faster “Return on Carbon.”

This Isn’t a Trend. It’s a Transition.

In the words of Johnny Cash, “I’ve been everywhere”—and from Montreal to Boston, the message was the same: insulation matters because it impacts both embodied and operational carbon.

While North America contributes just 14.2% of global emissions, we’re still expected to lead. Material choice matters, but system design matters more. EPDs help, but the real insight comes from evaluating whole assemblies, from fasteners to finish, to pick materials that perform and reduce carbon.

More tools are coming, and with them, changes to specs and codes. Our job is to help designers and owners understand the environmental benefits spray foam delivers.

In the meantime, ask:

- What’s the carbon cost?

- What am I replacing with this?

- Is there a smarter way to hit the performance target?

If we want net-zero buildings, we need to rethink construction, from the ground up and the wall out. The sooner we start, the sooner we can brag about carbon numbers, not just R-values. And let’s be honest, we’ll probably get there before the Leafs win the Cup.

Direct any questions about the products mentioned in this article to Elastochem at www.elastochem.com or call 877-787-2436.

Spray Foam Magazine does not take editorial positions on particular issues; individual contributions to the magazine express the opinions of discrete authors unless explicitly labeled or otherwise stated. The inclusion of a particular piece in the magazine does not mean that individual staff members or editors concur with the editorial positions represented therein.

Disqus website name not provided.