Beverly Hills Recording Studio Topped With Spray Foam Roof by AM Construction

BEVERLY HILLS, CA–November 27, 2012–When it comes to recording studios, the sharp, angular foam that covers the walls are not only a common sight, but are perhaps the most oft-imagined vision of soundproofing. Not to be outdone, spray polyurethane foam also exhibits strong sound-deadening characteristics. Indeed, a recording studio in Beverly Hills, California opted for a spray foam roofing system for its soundproofing performance as much as for its insulating and sealing qualities.

The recording studio was upgrading its rooftop A/C mechanical units and ductwork when it opted to also replace its existing torch-rolled roofing system. Installing a spray foam roofing system was a no-brainer, considering the sound-sensitive nature of the studio's operation. AM Construction was contacted by the studio about the situation, for which AM proposed utilizing Henry PERMAX spray foam roofing products.

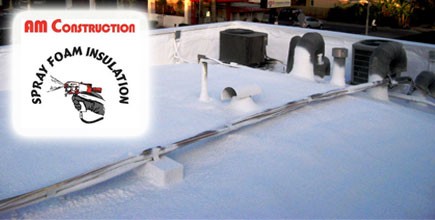

Removal of the existing torch-rolled substrate was not required; rather, AM primed the roof surface with Acryprime substrate primer. AM then sprayed an average of two inches of PERMAX 2.5 lb. closed-cell roofing foam across the entire 7,000 square foot roofing surface.

The application of the foam was relatively tricky due to the several new mechanical units, ductwork, extensive wiring and numerous roof penetrations. Furthermore, the roof itself wasn't comprised of a single flat surface, but instead had areas with different elevations. So, AM had to place an emphasis on spraying proper flashing at all of these critical spots. In fact, before the application even started, AM raised the mechanical units above the roof surface in order allow for the proper installation of flashing around their bases.

After the foam application had been completed, AM covered the new roof substrate with white PERMAX elastomeric coating. Approximately 3.5 gallons of the coating were applied for every 100 square feet, which translates to a dry thickness of about 60 mils. After the coating was applied, calcite granules were broadcast over the surface to finish the roofing system.

When all was said and done, the project took three days to complete. Now, the recording studio is not only enjoying the improved sound-deadening qualities of its new roof, but also the insulating and sealing qualities that compliment its newer, more efficient air conditioning system.

About AM Construction Spray Foam Co.: Based in Santa Monica, California, AM Construction specializes in spray foam insulation and roofing systems. AM Construction's service area includes the Southern California region, from Santa Barbara to San Diego. For more information, please use the contact details and links provided below.

Disqus website name not provided.