Simple to Spray in a Sustainable Way

SPRAY FOAM INSULATION – Long recognized for its sealing and insulating benefits, spray foam continues to gain widespread use in the construction industry. Spray foam adheres to most surfaces and expands to create a seamless, airtight building envelope. By effectively reducing air leakage and limiting infiltration of pollutants and allergens, spray foam increases a building’s energy efficiency and improves indoor air quality to create a comfortable environment. In addition to its sealing properties, spray foam offers superior thermal insulation. Specifically, closed-cell spray foam is often used where the highest R-value per inch is required as compared to conventional insulations like glass/mineral fibre and cellulose. Closed-cell spray foam is a multi-functional product that can act as an air, vapour, water and soil gas control barrier.

Creating a sustainable future

As a global leader in spray polyurethane foams, BASF is committed to driving sustainable solutions through chemistry. BASF helped lead the way in the replacement of hydrofluorocarbons (HFC) to hydrofluoroolefins (HFOs) in the polyurethane foam industry. The first WALLTITE® closed-cell spray foam to use this low-GWP chemistry was launched in Canada in 2020.

walltite® V5 – The Next generation

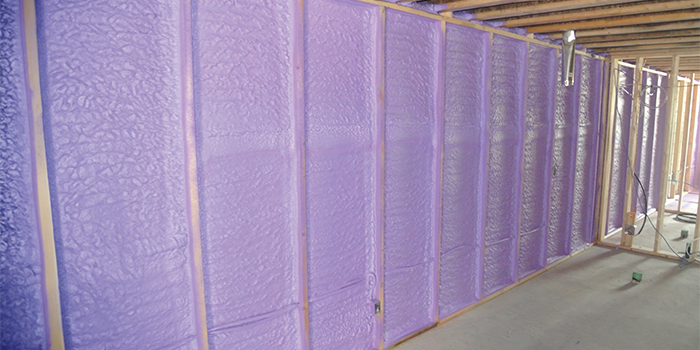

Years after the introduction of the first HFO-based chemistry for spray, BASF continues to make technological advancements with the introduction of WALLTITE® V5. For use in the Canadian market, WALLTITE® V5 is the latest closed-cell product in the portfolio. Besides its distinctive purple colour, the WALLTITE® brand is recognized for providing spray contractors with high-performance formulations for over 30 years.

Keep it simple and spray

WALLTITE® V5 is designed for ease of application which means spraying has never been so user-friendly. With a wide processing window, sprayers don’t have to waste time constantly adjusting temperature and pressure settings. WALLTITE® V5 combines an industry-leading LTTR value of 5.6/inch (CAN-ULC S770-15) with the added benefit of no wait time between passes. The ability to spray up to eight inches within 24 hours equates to substantial cost and time savings. This high-yield product is ideal for different climates and seasons. Whether you’re an experienced sprayer, or just starting out, WALLTITE® V5 is an easy-to-spray and efficient product that can provide a smooth, finished job.

V for Versatility

The versatility of WALLTITE® V5 makes it the perfect solution for a variety of applications including interior wall cavity fill, attic, and continuous insulation. Plan to use purple for your next projects.

Direct any questions about the products mentioned in this article to BASF Canada at www.walltite.com or 1-866-474-3538.

For use by SprayFoamMagazine.com & Spray Foam Magazine

Disqus website name not provided.