Francis Construction & Woodworking LLC Uses Closed-Cell Spray Foam To Create 'Spa Cave'

STONE MOUNTAIN, GA – December 3, 2012 – When homeowners were in the process of insulating their existing home with spray foam, they spontaneously decided to convert their basement into a cave-like spa made of closed-cell spray foam. Francis Construction & Woodworking LLC (FC&W) was the contractor called in to renovate the property as well as create the spa cave.

The homeowner's inspiration for the spa originated when they visited the Grove Park Inn, located in Asheville, North Carolina. The spa in Asheville had a waterfall and an in-ground Jacuzzi with a glass tile bottom. Crewmembers were already working on the exterior, interior, and landscaping of the 4,000 sq. ft. home when the customers asked them to replicate the spa. "It sort of just evolved from a meditation spot to a complete spa with a cave and everything else," said Nick Tverdich, Owner of FC&W. The new spa would be created in a 16 ft. by 12 ft. wide room in the basement.

To get a better idea of the owner's request, Tverdich and his crew visited the Inn before starting the job. The Inn's cave was created from gunite, which is made from solid concrete. Tverdich noted that closed-cell spray foam was also used in some areas. "We didn't have enough load-bearing supports for gunite [in the home]," said Tverdich. "So we used closed-cell spray foam to manipulate the structure."

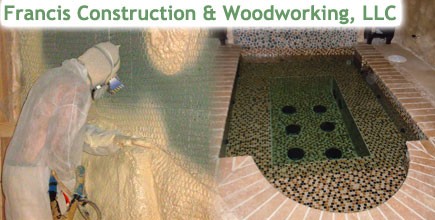

FC&W manipulated wood and chicken wire to form cave-like shapes after installing moisture resistant green sheet rock to board the walls and ceiling. They then applied Gaco Western 2 lb. closed-cell spray foam in varying thicknesses and carved it to create the atmosphere of a real cave. Boulders were created on the walls by applying 2-inch thick layers of spray foam and carving it into desired shapes. A ledge resembling a cave ceiling was tied into the existing framing of the walls, which hung about a foot down from the 8 ft. ceiling.

Other features had to be accounted for as well. FC&W installed about 400 fiber optic lines before the chicken wire was put into place. After the lines were sprayed with foam, according to Tverdich, they hung from the ceiling creating a stalactite affect due to the weight of the foam. A speaker system was also embedded in the foam.

To offset possible humidity issues, air conditioning lines were brought in and FC&W created space within the spray foam where the lines could be hidden. "Spray foam allowed us to customize air supply and return in the cave, which was important due to the spa temperature and humidity," said Tverdich.

FC&W used a Graco E-XP2 Reactor to apply Gaco U-8782 polyurea hybrid coating to parts of the spa that would be vulnerable to moisture, such as the area surrounding a built-in waterfall. Also, crewmembers applied an acrylic used to change the texture of the spray foam, making it feel more like real rock. The acrylics were covered with glazing and crewmembers used an airbrush in order to access the cave's crevices. FC&W purchased their ProPak 300 rig from Spray Foam Systems.

In order to contain their workspace while spraying, the crew created plastic walls to protect the rest of the home from odor and overspray. The Jacuzzi was covered for protection during application. The total spray area of the cave was approximately 800 sq. ft. and it took two crewmembers about a week and a half to complete the job.

As for the rest of the three-story home, FC&W renovated it from head to toe. According to Tverdich, the entire house was gutted in sections. They slated the roof of the home and had to re-frame the house due to mold damage. As the crew got to each area that contained fiberglass insulation, they slowly removed it and replaced it with closed-cell spray foam. "Nine out of ten times it was closed-cell," said Tverdich. "Unless we knew we had to run wire in some areas, like in between the floors where there was a bit of an air gap. Then we used open-cell."

The owners resided on the middle floor of the three-story home during most of the renovation process and were very pleased with the outcome of their newly renovated home complete with its new cave inspired spa.

About Francis Construction & Woodworking, LLC: Francis Construction & Woodworking LLC is located in Griffin, Georgia. For more information about Francis Construction & Woodworking LLC, please use the contact details and links provided below.

Disqus website name not provided.