Building Excellence

Spray Foam Magazine – Summer 2025 – Inside PMC’s Lakewood, NJ facility, precision meets purpose. Machines and guns are assembled in stations, and hose components are laid across tables that stretch a building’s length ready to be wrapped and boxed. Engineers work on perfecting equipment and processes. The focused attention of skilled employees and the unwavering commitment to quality define every step of production. This is every day in the life of building PMC machinery.

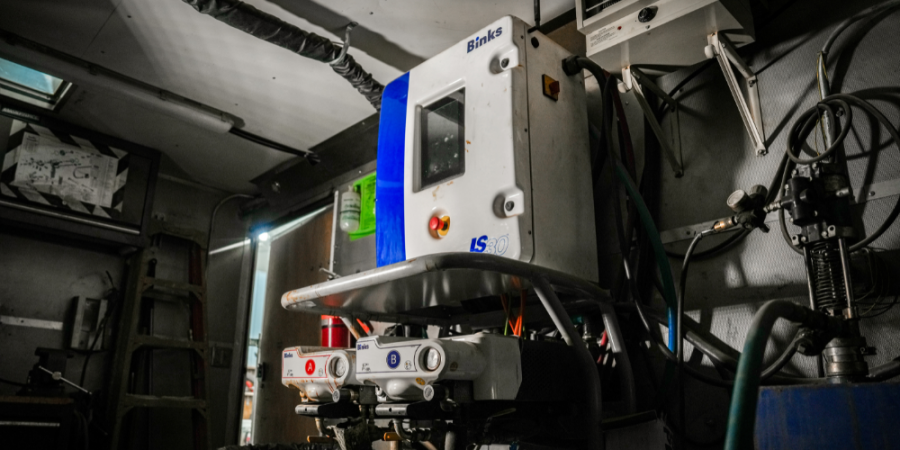

At the heart of the plural component application industry lies the proportioner, a sophisticated piece of engineering that ensures precision heating and output. More than just a machine, a PMC proportioner is a testament to American craftsmanship, built to endure the toughest job sites and deliver unparalleled performance. From selecting top-tier parts from American suppliers to rigorous quality assurance testing, every proportioner leaving their facility carries a 100% satisfaction guarantee, and the PMC promise to be “Durable, Reliable, and Smarter.”

So, what does it take to build America’s tried and true proportioner? Let’s see.

The Start of the Build: Precision Engineering & High-Quality Materials

Every PMC proportioner starts with a high precision design. The mechanical and electrical engineers who designed and refined these machines lay out a meticulous process for each build. They collaborate with local tooling and machine shops that support the same stringent quality standards used in their own machine shop and sister company, Komo Machine, Inc. In addition to the tooling company’s inspection process, PMC inspects every part using state-of-the-art QA equipment, ensuring it meets their exact specifications and tolerances. If a part or component does not meet all quality criteria, it is not used in a PMC machine.

With plans and parts in place and skilled workers ready, assembly begins.

Assembly: Expert Workmanship

Technicians assemble the body, electrical panel, hydraulics, and components ensuring that the proportioner will function precisely. Each stage of assembly undergoes thorough inspections to guarantee accuracy and reliability. By prioritizing quality from the very first step, they lay the foundation for a machine that will perform optimally in the field.

PMC prides itself on having technicians who have been with the company for many years and have comprehensive knowledge of every machine they build.

Quality Assurance: Testing for Perfection

Before a proportioner leaves their facility, the finished machine must pass exhaustive testing. QA technicians put each machine through simulated real-world applications, verifying pressure balance control, inlet monitoring, temperature regulation, and several other inspection points. These tests replicate the customers’ demanding conditions in the field, ensuring that the equipment will perform flawlessly when it matters most.

A PMC technician is doing the wiring for the heater thermocouple.

At PMC, failure is not an option. If a unit deviates from their exacting standards, adjustments are made and retested until they achieve perfection. The QA team takes pride in their role, knowing that their diligent work guarantees a product that meets and exceeds industry expectations.

Ready for the Field: Supporting American Industry and Beyond

Once a proportioner passes final quality assurance, it is crated for shipping. PMC machines find their way to rigs across the U.S. and beyond, becoming integral to countless construction, insulation, and coatings projects.

PMC’s commitment to American manufacturing supports jobs and industries throughout North America. But their dedication doesn’t end with the sale—along with our highly trained distributors, they provide ongoing customer support to ensure that their machines deliver durability, reliability, and efficiency for years to come.

More Than a Machine: A Promise of Quality

From raw materials to a fully assembled, American-made proportioner, the journey of every PMC machine is a testament to precision, dedication, and quality. PMC’s mission ensures that every unit leaving their facility is more than just a piece of equipment, it is a promise to their customers and the industries they serve. At PMC, they don’t just build machines, they build trust, one proportioner at a time.

Disqus website name not provided.