Keeping Connected in the Field

HUNTERSVILLE, VA – February 1, 2019 – As the spray foam industry continues to grow and more contractors enter the field, the competition for jobs increases and further challenges owners to provide accurate and professional installations while making sufficient profits for their company.

For the vast majority of contractors, it is a fairly simple process for their sales team to visit a job site, measure the appropriate areas, create a proposal and quote, and get the acceptance from their customer. Some contractors use industry-specific software to ensure accuracy on their proposal and delivery to the customer, while other contractors use an Excel spreadsheet to develop their pricing, a Word document for their proposal, and various methods to deliver the proposal. In most cases, there are two people involved—the salesperson and the person authorized to approve the proposal. While there may be bid revisions, change orders, etc., the communication in many cases involves two people. With only two people involved, the opportunity for mistakes and miscommunications are minimized with the buyer expectations and what the contractor plans to install.

When the proposal is approved and the job needs to be scheduled and installed, the number of people involved in the process increases and the opportunity for data and information slippage is heightened. In many cases, here are the people involved: The employee with the contractor that handles scheduling, the crew members and supervisor that installs the product, the person that is responsible to collect the product usage information, the person responsible for the hours on the job for payroll, etc. There are a lot of people and moving parts involved with the execution of the job. Many times the job is completed without any issues.

In other situations, problems may arise and change orders and adjustments have to be made on the fly. Whether the job is installed without any problems or there are issues that have to be accounted for, the profitability of the job and the documentation of accurate and critical information is at stake. The owner of the insulation contracting firm is interested in how profitable the job actually produces. For example, how much product did the crew members actually install compared to what was quoted? Were there change orders? Were they documented and approved properly? How many hours were spent on the job by crew members? Were there additional expenses for the job not accounted for? Did his crew clean up their area after their work? Does the owner have photographs to document their work (ie. A before and after photograph for historical purposes)? As you can see, a lot of critical information is at stake and the owner is responsible for everyone doing their job properly and recording critical information throughout the day, job to job, and reporting these details to their system of record.

In most cases in our industry, the crews may write down on the work order how much product they used and their hours on the job and leave it for someone at the office to read and hopefully interpret their hand writing correctly. In some cases, they lose the work order and someone has to guess at what took place or make multiple phone calls for clarification.

By using applications available digitally, contractors and field technicians can begin to minimize the inaccuracies and delayed information reported using a manual process.

This manual process allows for mistakes and lack of detailed information on the actual job performance as well as wasting valuable time communicating back and forth. This type of process multiplied for each job performed in a given week leaves the business owner in a precarious situation not fully understanding his actual profits or losses by job. This is not a formula to build a sustainable and profitable business for the owner.

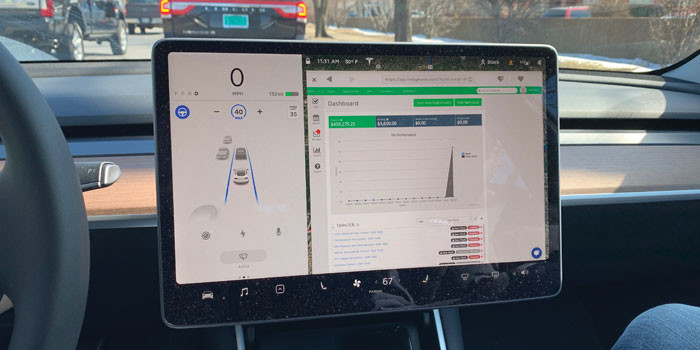

Many proactive contractors in our industry are investing in tools for field technicians by implementing new technician apps for their crews. Their goal is to replace the manual process that can cause inaccurate and delayed information reported.

There are technician apps available specifically for this industry to help companies with accuracy and timely feedback from their crews. Here are just a few of the benefits:

- No more printed work orders; Save money on paper and ink

- Record product usage and time on the job in real time; Ensure crew accountability and reporting in real time

- Understand job profit or loss when the crew leaves the job site; Instant visibility into job performance

- Photograph capability; Crews can take before and after jobsite photos for documentation that does not reside on their personal mobile phone

If you are looking to improve the information flow and documentation from your crews to the home office, now is the time to investigate new software tools available for the insulation industry. •

Disqus website name not provided.