Trust Documentation, Not Social Media

Spray Foam Magazine – Spring 2025 – If you weren’t present at the SprayFoam Convention and Expo, you missed a great week—including the SFWW Rig Show and Spray Foam Magazine’s Big Game Party with their Contractor of the Year awards. This weeklong event included attendees from all over the world, industry associates getting together, communicating face-to-face, sharing ideas, knowledge and personal experiences, all to better our industry. Thanks to all the attendees, exhibitors, sponsors and industry supporters for making this event what it is today. It’s getting better every year!

Each of the Breakout Sessions during the SPFA Convention were well attended with good interaction between the presenters and session attendees. These sessions varied from industry compliance and safety information, new equipment, new products and techniques, chemistry, performance in application, to business strategies. The Panel of Industry Experts was a great idea and allowed for spirited interaction with the audience.

One of the highlights was during the SFWW Rig Show, where contestants had the opportunity to compete in the Fifth Annual Countryside SprayOff Competition. In addition, the Polyurea Development Association (PDA) held their First Annual Polyurea spray competition.

While many may have felt that the competitions were “easy,” especially for the polyurea part, a special challenge had been incorporated—documentation. The subject of this article.

So, what does “documentation” really mean? Documentation may include, in no certain order and not limited to:

- Materials of use Product Data Sheets and Safety Data Sheets

- Specification Information

- Equipment Manuals, operation, parts, repair

- Application log forms

- Industry Standards

Product Data Sheet / Safety Data Sheet

There are a variety of polyurea coating systems, as well as spray foam systems on the market. They are NOT all the same. There was an excellent presentation by Mr. Tom Harris during a breakout session at this past SPFA Conference titled, , “SPF Information: Trust but Verify.” He made an excellent point made here, especially when comparing various supplier’s product data sheets on physical property information and testing. Make sure the same type test is used, rather than just comparing numbers.

This played a key role in the competition areas of this conference. Information here would note the minimum and maximum pass line requirements, as well as information of gel and set time for polyurea systems. It’s not just about making it look pretty, or having “butter” with spray foam, but what is required for performance.

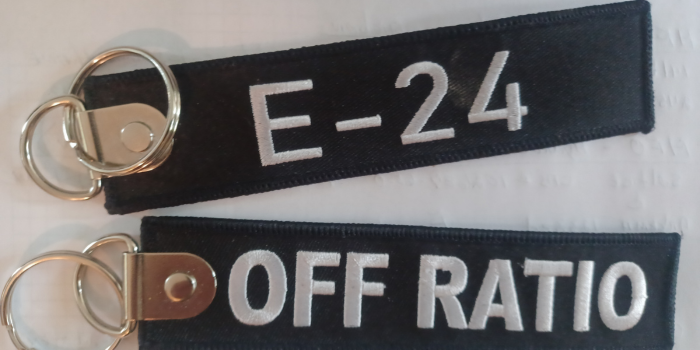

"Thanks to Mr. Josh Cotner at the rig show, I picked up these two great hang tags, which are very appropriate in our plural component equipment application work." -Dudley J. Primeaux II, PCS, CCI

A prime example are the various social media posts where one is having trouble applying a polyurea coating system, or spray foam for that matter, and posts about the issue. In many cases, not enough info is provided, then you have a quantity of responses that may not address the actual issue. Referring to the specific product’s data sheet can provide one the recommended starting points for their specific system.

For Safety Data Sheets (SDS), this is the correct information regarding the Hazard Assessment of the material being used. With that, one needs to also understand what the Risk Assessment is for these materials in use. This is where ones go for this information, NOT what someone posts on social media as to what they are doing. We often see many posts on social media, with applicators using improper and unsafe practices, as well as incorrect PPE use.

Ah, but we know the old saying, “Well they haven’t caught me yet, so send it…”

The subject of Specifications was already discussed in the Show Issue 2024 of Spray Foam Magazine, so no detailed discussion on the subject will be provided here, except for one very important point—please read the specification before bidding or starting the work so as to make sure it is properly written and one can perform that task with the expected performance results!

Equipment Manuals

Yes, equipment manuals. Very important information to have with you in the trailer on the job site.

While in years past, these were all various binders, printed hard copies if you will, that contained valuable information on setup, operation, parts, and YES, a troubleshooting section! While most really don’t have the printed versions with them anymore, “new” technology in the palm of our hand allows us to access and save these electronically. You have the tool, use it!

Then there is the infamous “E24” posts and what is the issue? On most newer spray units, a QR code appears when there is an equipment issue. Use that tool in the palm of your hand to scan that code, and guess what? It takes you to a website with information on that issue and how to resolve. Much faster than taking a picture and posting on social media asking a question and waiting for the numerous responses.

Daily Application Log Forms

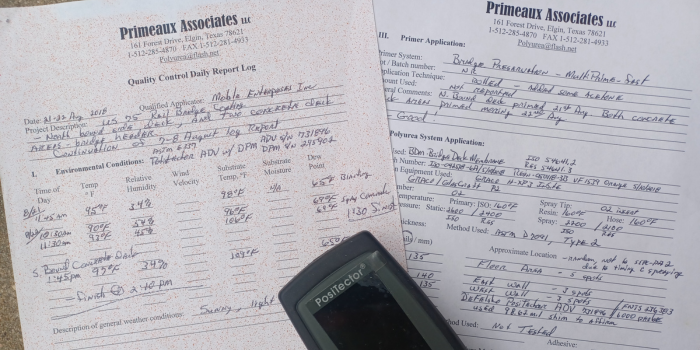

In most all industrial coating projects, a project specification is present, hopefully properly written and reviewed. Most all of these specifications require the contractor/applicator to complete and submit daily application log forms, but how many actually perform this? As tedious as this may seem to some, it is a very important aspect of spray foam and coatings work.

These forms can be self-prepared, but many of the system suppliers offer these to the user. The PDA, as well as the Spray Polyurethane Foam Alliance (SPFA), offers nice form templates to use as well. This form should include information:

- Project description, purpose and date

- Environmental conditions, at the job site

- Surface preparation used

- Primer use, how applied, primer lot #’s

- Foam or polyurea systems used, how applied, and lot #’s

- Any testing performance that confirms proper application

Believe it or not, having these prepared and documented can help keep you, the applicator, out of trouble if there is an issue down the road.

Industry Standards

Last but not least, we must discuss Industry Standards. These are standards, such as ASTM or ISO Test methods, AMPP (formerly SSPC and NACE), and the SPFA application procedures and performance methods for example. These are compiled by a representation of industry peers and officially approved by the respective organization. Refer to these in your work.

A prime example here relates to the PDA Polyurea spray challenge. While many thought that the simple two foot by two foot panel was too easy to spray, the challenge was to comply with SSPC-PA 2 Procedure for Determining Conformance to Dry Coating Thickness Requirements, Level 2. Of the 31 contestants, only 4 barely met that requirement.

An opinion post, or this is the way “I did it,” will not necessarily get you out of trouble if there is an issue with your application work.

Conclusion

Documentation is one of the most important tools one can utilize for successful, professional application work. This not only applies to the large industrial polyurea coating and spray foam projects, but even the small ones, as well as any residential spray foam projects. Don’t get me wrong, I’m not against social media posts, they are very helpful at times. But use the documentation first. And always be a professional in your work, regardless of the size of the project.

Published by Spray Foam Magazine

SprayFoam / Spray Foam Insulation

Disqus website name not provided.