SPF Strengthens Buildings

Back to Education Center | Architect's Guide | Building Envelopes and SPF

The Structural Integrity of Buildings

The primary load-bearing structures of your home are the walls. For wood frame construction, the walls are compressed by the downward-exerted force resulting from the combined weight of the roof, including trusses, decking, and shingles, as well as anything on top of the roof like debris or snowfall. Additionally, wind exerts a lateral force on the walls of your home, potentially distorting their perpendicular framing with what building scientists call a “shearing force.” All building code requirements mandate that residential walls be constructed to withstand these forces. Despite the implementation of these requirements, walls that merely meet the minimum requirements can be prone to movement (creaking, shifting, shaking, etc.) during high-wind events like tornadoes or hurricanes.

High-density closed-cell spray foam insulation can reinforce exterior walls when sprayed in stud cavities. Closed-cell SPF adheres to both the exterior sheathing and wall studs to enhance the overall structural integrity of a wall assembly. With the installation of spray foam, an exterior wall becomes more rigid and thereby more resistant to compression and shearing, and so it can be said to have a greater “racking strength” than a typical wall assembly.

In fact, research conducted by the National Association of Home Builders (NAHB) has shown walls installed with closed-cell spray foam have a racking strength up to 300% greater than walls without it.

Testing Racking Strength

When a shearing force acts on a wall, it can be distorted from its intended rectangular shape to that of a parallelogram. Testing a wall assembly’s resistance to shearing forces entails involves a special test overseen by building engineers. A “racking test” typically begins with building an 8 by 8 assembly wall and placing it in a testing frame. Engineers secure the base of the assembly wall to the testing frame and then apply a lateral (horizontal) force to the upper unsecured part of the wall assembly. The force is increased in 400 lb. increments until the wall assembly fails.

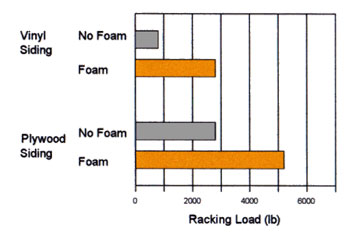

In one particular study [1], wall assemblies installed with and without spray foam insulation were tested. The two exterior-facing building materials that were tested included vinyl siding over 15-lb. building paper and textured plywood siding. All wall panels were faced with half-inch drywall on the interior-facing side, with studs spaced 16 inches on-center. In the SPF-applied group, the stud cavities of the wall assemblies were filled with closed-cell spray foam (1.5 lb./cu. ft. density). The graph indicates the wall assemblies that were installed with SPF added significant racking strength, as well as deforming less and offering greater resilience with each applied force.

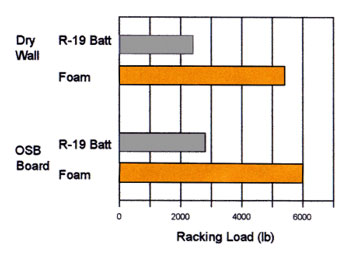

In another study [2], walls installed with closed-cell spray foam (average density of 2.26 lb./cu. ft.) were compared to walls installed with traditional fiberglass batt insulation (R-19, per building code requirements). One comparison involved wall assemblies with both sides faced with drywall, while another involved wall assemblies with one side faced with drywall and the other with OSB (oriented strand board). Both comparisons utilized steel studs, spaced 24 inches on-center. As with the graph above, the one below shows a clear strength-enhancing advantage to installing closed-cell SPF.

Put simply, wall assemblies installed with closed-cell spray foam insulation outperform the other conventional wall assemblies.

Sources

- Test results are reported in "Testing and Adoption of Spray Polyurethane Foam for Wood Frame Building Construction" (May 25, 1992) prepared by NAHB Research Center for The Society of the Plastics Industry/Polyurethane Foam Contractors Division.

- Test results are reported in a letter from Bob Dewey, Mechanical Engineer, NAHB Research Center to Mason Knowles, The Society of the Plastics Industry/Spray Polyurethane Foam Division (November 18, 1996).