What are We “Shooting” Today?

Spray Foam Magazine – Winter 2025 – After reading the interesting article “Battle-Tested,” by the FOAMGINEER in the Spring 2025 Issue of SprayFoam Magazine, it got me to thinking. And yes, I do read the articles, hope you do as well! It is interesting to see the neat application areas of our spray applied thermoset technologies, including SPF and polyurea, not only protecting structures but also protecting human lives.

Some of us may remember the iconic line, “The heart Ramon. Don’t forget the heart. Aim for the heart, or you’ll never stop me.” These words were spoken by the poncho clad Joe, the Stranger, when facing off against the bad guy Ramon Rojo in the original spaghetti Western “A Fistful of Dollars,” 1964. With a steel chest-plate hidden beneath his poncho, Joe taunts Ramon, who becomes very distressed as the rifle shoots, though knocking Joe to the ground, it seemed to bounce off the hidden “ballistic steel-plate.”

So, what does this have to do with the polyurea spray technology one may ask? People may not realize that the poncho provided more than just a cover to hide the plate, but it also provided protection from the resulting shrapnel generated from the projectiles striking the plate. This shrapnel, if not contained, would be detrimental to “soft” areas. Here is where the polyurea spray technology fits.

If you get a chance, look online at high-speed-camera videos of high velocity projectiles striking a ballistic plate. One would be surprised how that projectile disintegrates with the resulting high-velocity shrapnel generated and flying off. Much of this work is done by Oregon Ballistic Laboratories.

In 2014 an excellent review, Body Armor 101, of current hard and soft body armor was discussed in Recoil magazine, Issue 15. In this review, numerous polyurethane (PU) and polyurea (PUA) elastomeric systems were noted as the spall protection material over various body armor substrates, it traps shrapnel. The PU and the PUA are part of a composite system that provides protection, not the coating used alone.

Is Polyurea Spray Bulletproof?

Over the past years, many have seen marketing promotions from various companies claiming their polyurea spray is a bulletproof shield coating material. When one sees the reports, pictures, and videos, the projectiles have passed completely through. To get a true understanding, let’s have a look at what literally bulletproof means, from the standpoint of high velocity projectiles:

Bulletproof—impenetrable to bullets!

Well, it’s very interesting. From a figurative standpoint, bulletproof may mean that something is reliable, or resistant to failure. Of course, the word “failure” can be interpreted depending upon the situation.

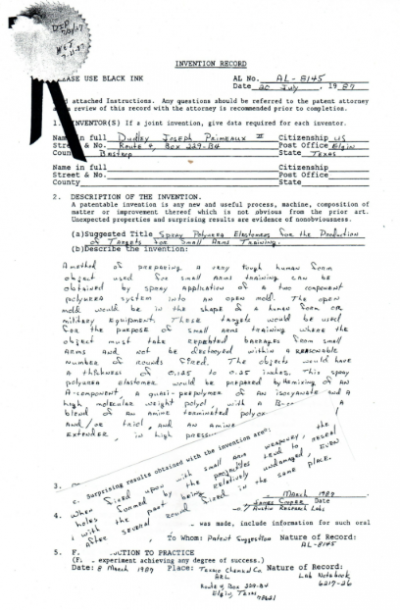

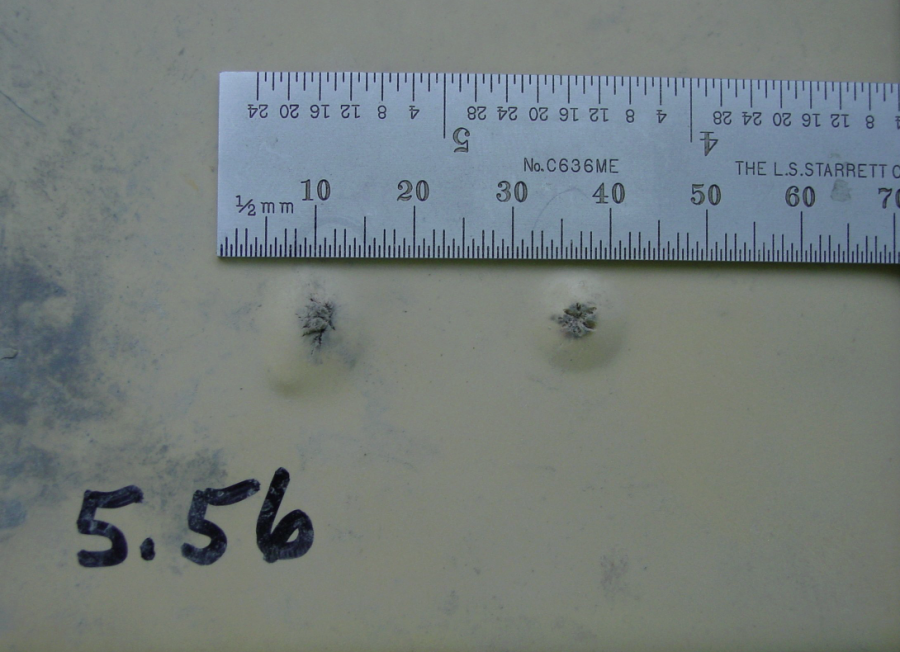

Back in 1987, a year after the polyurea spray elastomer technology was developed and demonstrated, an Invention Record was filed on the use of polyurea spray to prepare small arms targets for training purposes. When applied at 125 to 250 mils (~3 – 6 mm) in thickness, the projectiles did pass through, but the holes formed tended to reseal, thus allowing for multiple use. This was found to be true even for the small .22 caliber projectile. So figuratively, the polyurea coating may have been bulletproof, but literally it was NOT! Ah yes, the marketing “play on words” here.

In using NIJ – National Institute of Justice testing protocols for evaluating and certifying bulletproof vests, various levels of certification are provided. These are provided in Table 1 below:

One of our industry associates in Alabama, and many know who that is, enjoys shooting as much as I do here. He too has also shown in various videos and demonstrations that “polyurea spray” by itself does not readily stop a high velocity projectile. PUA is NOT bulletproof by itself.

Another industry associate in Central Texas has been working with a U.S. Government project demonstrating a specific polyurea composite aircraft fuel cell. This work has shown that when the flexible fuel bladder is struck by .50 BMG and 20-mm rounds, penetration does occur but the strike hole essentially “seals” itself thus minimizing the leakage.

This even occurs when the projectile is tumbled at -40°C exposure! Bulletproof here? Well, no, but impressive to say the least. By also incorporating the secret powder in the NewPIG® absorbent mats, additional swell sealing occurs with hydrocarbon contact.

A little over 10 years ago, I had the opportunity to work on a commercial U.S. military application using a specially formulated PUA applied to a special light-weight composite panel. The applied PUA was to protect the panel from certain liquid exposures, possess anti-microbial properties, and have specific fire-retardancy capability. While challenging to meet all requirements, it was an exciting project to be involved with. At one point in time, over 1500 military aircraft had been retrofitted with these PUA-composite panels. Based upon projectile hit locations in the protected aircraft, they estimated that over 900,000 lives had been saved due to these panels within two years of implementation.

Now there are PU/PUA based systems, which are processed via a vacuum molding process, to then produce a solid article that is in fact bulletproof. Much of this work has been completed by The University of Missouri – Rolla, the University of Southern Mississippi, University of California – San Diego and the Naval Research Lab (NRL). But these are not polyurea spray elastomer systems alone.

A good overview and testing information for the polyurea spray technology in these ballistic applications can be found in Paper # 2017-5487261 as part of the 2017 Department of Defense – Allied Nations Technical Corrosion Conference, written and presented by a great associate and I, based upon years of work in the area.

CONCLUSION

Do some polyurea spray elastomer systems possess some form of ballistic protection? YES! Are these systems alone bulletproof? NO! So maybe a better term to use here related to polyurea spray coating materials is that they possess some form of ballistic resistance, not bulletproof. Composite materials, based upon polyaramid fabric, ultra-high molecular weight polyethylene or ceramics, coupled with a polyurea spray system provide for true bulletproof materials. The best part of all this, I get to combine my technical work with a favorite hobby and interest!

A sample PUA BallisticPanel, first supplied to the U.S. Army’s 160th Special Operations Aviation Regiment (SOAR), with the author’s decommission SIG M17 used by the Texas 3rd Armored Cavalry Regiment,

4th Squadron“Long knife”—S “Stetson” Troop. This sidearm was carried in the various

aircraft fitted with the sespecial panels, Operation Inherent Resolve.

Disqus website name not provided.