I Got a Polyurea Job! Now Who Has the Best Deal on Material?

Spray Foam Magazine – Fall 2025 – Now that things are warming up here in the Northern Hemisphere, industrial coatings work is coming into play. Unfortunately, we see this request more often than not in various social media groups—people looking for the best deal if you will. For those of us in the industrial coatings market, this should bother you. Typically, no information is provided by the poster as to what the project is, or the actual service conditions. But it is usually pretty obvious they are looking for the best price for materials, and not the best or proper material for the project.

Contrary to what some may think, the “best deal” is not just price. Since it is known that not all polyurea systems are created equal, many of these systems are designed for a specific application. There is no “one size fits all” for this technology.

All projects should have a specification. A bid document is not a specification! The specification is the legal document, providing the required information on what is to be used as well as what is to be performed. This will help ensure that the right material is used and applied properly to achieve the required performance. This was discussed in detail in the 2024 Show Issue of Spray Foam Magazine.

Support from a supplier for the project should be considered when looking for that best deal. Since there are both aromatic and aliphatic based systems, the supplier can direct you as to the proper type systems. Remember, aromatic based systems, while perhaps having UV stability, are NOT UV color stable. Most aliphatic based systems are both UV stable and UV color stable but do carry a higher “price tag.”

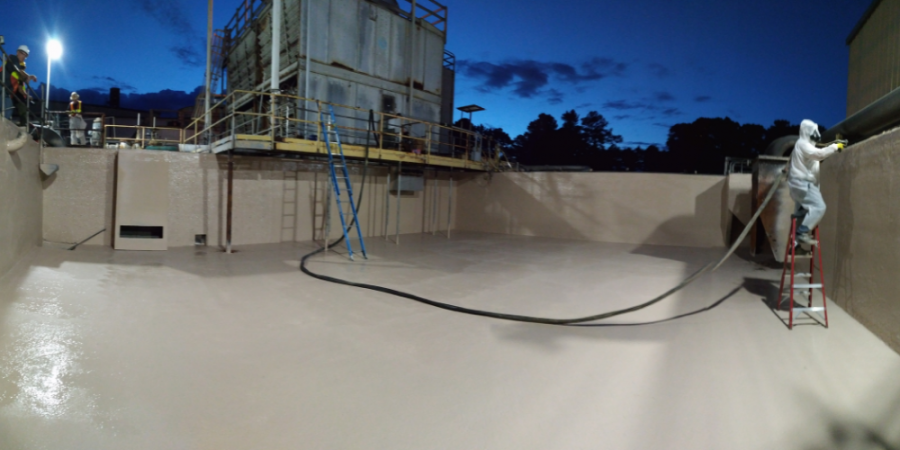

Polyurea coating projects are not just “show up and start spraying,” as there should have been quite a bit of thought and preparation beforehand that makes for a successful application. Almost all of these projects may require some prep work and repair, as well as the industry required proper preparation work.

The Best Deal

So, what should the “best deal” look like for polyurea spray coatings work?

First and foremost, the best deal is the proper material for the project, or what specifically is specified. Indicate in the inquiry as to what the project is that is being worked on. What is the substrate? Is this atmospheric exposure or constant immersion? What is the chemical exposure? Are there cleaning chemicals that will be used? etc.

What support is being offered by the system supplier? Often a technical support person is made available for these large projects to either oversee the project or help with the required reporting. Of course, this can be at a cost and can be required as part of the work specification. Developing a relationship with a supplier can be highly productive as opposed to “price shopping.”

What if one encountered a problem with the material on the project? Is that “low-cost” material going to be supported by the supplier, or are you on your own?

Have you bid the project properly, considering all the costs? I have been involved in several projects over the years where material could have been supplied for free and the contractor still would not have covered their costs just to meet a low bid.

Does the work specification require a third party inspector? This will be noted in the project specification and will be a direct cost of the work. But an experienced on-site inspector should ensure the project work is completed for successful performance.

The goal here with this article is not meant to offend anyone, nor discourage from transitioning from spray foam work to performing polyurea coating work. It should make you aware though that sourcing any old open-cell or closed-cell spray foam for a house insulation project can be totally different than using the proper polyurea system for a project. And as the old saying goes, “Cheaper is not Better!” It should be the overall “deal” that should be considered.

A Prime Example

A few years ago, I was involved in a legal situation related to polyurea spray coating work at an institutional facility. The contractor started out properly, with the specified material for the project, a system that was designed for the specific application work. Of course, there was a failure shortly after the project was completed and the facility was put back in service.

Through the investigation work, it was determined that the total square area covered did not match the amount of material obtained from the specified supplier. The “math” was not “math-in” if you will. Records then revealed that the contractor decided to use a local, less expensive polyurea material to complete the project. The idea was to save some money, as the initial bidding was not quite right.

I’m not sure how much money was actually saved here. Most of the initial application work had to be removed, re-prepared and the proper material applied. Not only was that a “cost,” but there were also costs related to down-time of the facility, as well as the stress put on the residents of the location.

And while this may be a touchy subject, not only does this apply to material, but also equipment. Using non-OEM aftermarket parts may put processing work in jeopardy. There are some excellent quality aftermarket parts, but sourcing hoses, etc. at a local hydraulic shop may not play well in your favor. And picking up a pressure gauge at a local hardware store may have internal components that are not compatible with the chemistry of the liquid components on the systems being applied. One’s overall safety needs to be considered as well.

A little known fact in the industrial coatings market and application work, modification of equipment, or use of non-OEM assemblies, is a violation of the work standard practice. An on-site third party inspector could write one up and file a non-conformance report, which could result in application work delays, or even loss of the project work.

CONCLUSION

Many in the spray foam business are expanding out into the polyurea spray coatings world, and that is a great thing! But keep in mind that you are transitioning from a commodity type foam business to a specialty industrial coatings business. One may get away with best deal / price in the commodity spray foam business for some projects, but that is not the norm in the specialty polyurea coatings business. Some may not agree with this, but these are the facts in industrial coating work and having successful performance in the work. Communication is highly important with the system supplier to ensure the proper type of material is being applied to the project work.

Disqus website name not provided.