SPFA’s A-value Initiative

Spray Foam Magazine – Fall 2025 – As insulation contractors, we understand the basic science of heat transfer—conduction, convection, and radiation—all of which depend on the building’s surface area (size), the temperature difference between indoors and out (climate) and, of course, the materials and methods we use to construct building enclosures.

Traditionally, building insulation is used to control conductive heat transfer, quantified by its thermal resistance. The basic principles of conductive heat transfer were quantified by Joseph Fourier, a French physicist, in 1822.1 Fourier defined thermal resistance, which is a measure of a material’s thermal conductivity and thickness.

“R-value” (a shorter term for thermal resistance), was proposed in 1945 by Everett Shuman, who, as Director of Penn State’s Building Research Institute, continued to promote their adoption. R-Values were later widely applied to industrial and residential insulating materials and helped customers make more energy-efficient choices.2 The concept of R-value made it easier for consumers: The higher the R-value, the better the resistance to heat flow.

During the U.S. energy crisis in the 1970s, there were a few manufacturers and contractors that were misrepresenting the R-value performance of insulations. The U.S. Federal Trade Commission stepped in and developed the R-value Rule3 in 1979 to help protect consumers from inaccurate performance claims. This regulation requires manufacturers to test and label insulation products using specific laboratory test procedures (typically ASTM C518)4 that allow direct comparison of insulation products.

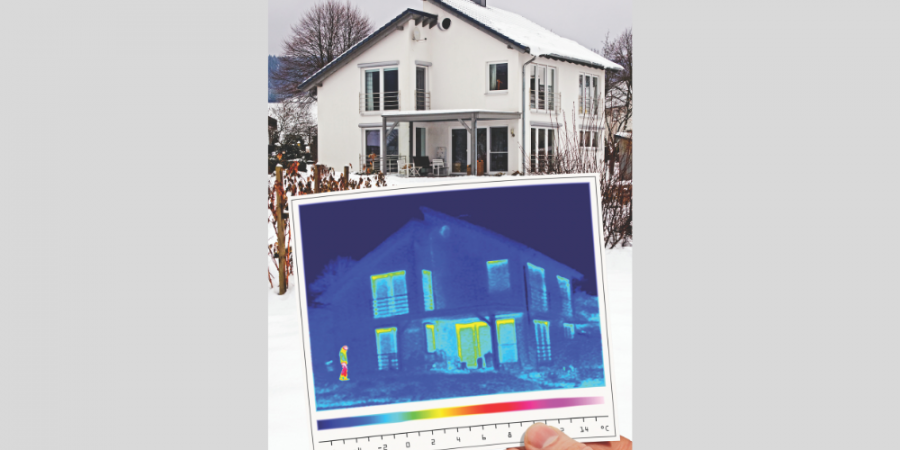

While R-value remains the cornerstone of thermal performance, it does not fully capture the reality of building enclosures. Air leakage—often overlooked—plays a crucial role in overall energy efficiency. It leads to conditioned air escaping, unwanted moisture migration, and compromised indoor air quality – all of which require more energy needed for heating and cooling. Energy codes and modeling software attempt to address building energy use through prescribed R-values and maximum air leakage rates. However, these codes and calculations use R-values performed under laboratory conditions that eliminate air movement through the insulation sample.

Here’s the catch: real-world buildings don't operate under lab conditions. Air permeable insulation like fibrous materials can allow air movement through the insulation, diminishing R-value far below that measured in the lab. In contrast, air impermeable options, like certain foam plastics, maintain more consistent performance. R-value is also temperature-dependent, typically measured at a mean value of 75°F—another mismatch with field conditions.

To solve these discrepancies, researchers at the National Research Council of Canada (NRCC) introduced a new methodology in 2009.5 These researchers first measured R-value and air leakage of an actual wall assembly. The R-value of the assembly was measured using a guarded hot box apparatus described ASTM C13636 with more realistic Canadian climate conditions of 68°F on the inside and -4°F and -31°F on the outside. Next, the same wall assembly was tested for air leakage using procedures described by the present-day ASTM E23577, adopted by ABAA.8 Using these measurements, a computer simulation was performed using hygIRC9 software account for air movement through insulation, they developed a comprehensive approach: the Wall Energy Rating (WER) method.

This research lays the foundation for A-value—a more representative metric that accounts for both insulation and air leakage under realistic conditions. With A-value, the industry moves closer to measuring what truly matters: how assemblies perform in the environments we live and work in.

Over the next several months, SPFA will be working with researchers and developing educational materials about A-value for contractors. Contractors can then discuss the A-value concept with engineers, architects, builders, code officials and consumers to promote the use of air-impermeable insulations like spray foam.

Direct any questions about this article to Rick Duncan at rickduncan@envelogic.com

Sources:

Fourier’s Law of Conductive Heat Transfer

R-value Historical Marker at Penn State University

R Values Historical Marker

Federal Trade Commission - Trade Regulation Rule Concerning the Labeling and Advertising of Home Insulation (“R-value Rule”) – Chapter 16 of the Code of Federal Regulations, Part 460 (16 CFR 460). eCFR :: 16 CFR Part 460 – Labeling and Advertising of Home Insulation

ASTM C518 Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus, ASTM International, 2021. University, Poultry Engineering and Economics Newsletter, Issue 43, 2006

Energy Rating of Polyurethane Spray Foamed Walls: Procedures and Preliminary Results, Elmahdy, A.H., Maref, W., Swinton, M.C. and Tariku, F., National Research Council of Canada Report NRCC-50857, June 2009

ASTM C1363 Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus, ASTM International, 2019.

ASTM E2357 Standard Test Method for Determining Air Leakage Rate of Air Barrier Assemblies, ASTM International, 2018.

Air Barrier Association of America, www.airbarrier.org

hygIRC – An advanced hygrothermal modeling software developed by A. Karagiozis at National Research Council Institute for Research in Construction, 1993.

Disqus website name not provided.