Passive Precision

Spray Foam Magazine – February 2025 – Kevin Erickson is committed to creating a passive, multigenerational, high-performance, all-electric steel barndominium that delivers comfort and energy independence. The Spray Foam Magazine team visited this notable project on a five-acre lot in Parker, Colorado, and discussed with Kevin the role spray foam plays in realizing his goals.

Europeans have long prioritized energy efficiency, and many new builds focus on sustainable, cost-effective homes. The Passive House (or Passivhaus) standard originated in Germany in the early 1990s, developed by Dr. Wolfgang Feist and Professor Bo Adamson, based on 1980s super-insulation research. This concept is gaining traction in the U.S. because it focuses on energy efficiency. However, Passive House also aims to make homes more comfortable and affordable to operate, not just to cut carbon emissions.

Kevin and his wife Cyndi want their new home to show what’s possible with passive house standards. They aim to build a comfortable, energy-efficient, and self-sufficient home. While this is their first energy-independent project, they have spent a long time planning it. Cyndi is designing the building, and Kevin is handling the technical details. To meet their goals, they included high-performance insulation, thermal mass, efficient HVAC, a large solar and battery system, well water, a cistern, rainwater collection, and a septic system.

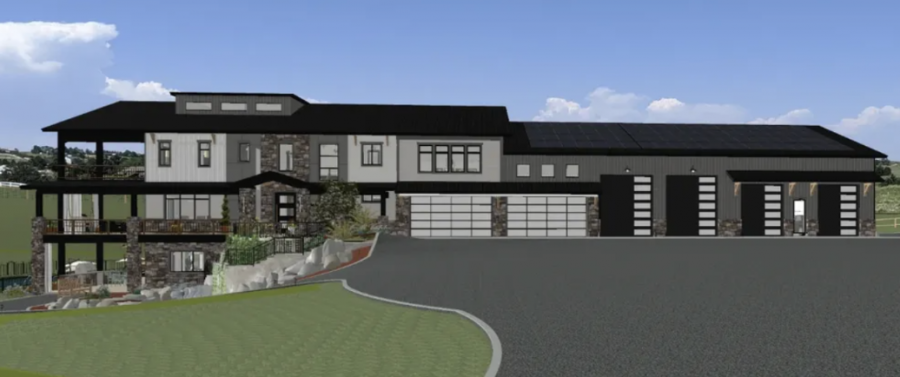

The barndominium is a two-story steel building with a basement, offering just under 10,000 sq. ft. of living space. The basement is an accessory dwelling unit (ADU) for Kevin’s parents. The 8,500-sq.-ft. shop and garage will hold vehicles and space for Kevin’s electric car projects.

After researching all options with meticulous planning, the couple chose spray foam for the home’s under-slab insulation, a choice core to their passive house approach. Its properties support hydronic floor heating, vapor and radon protection, and high durability for the shop area.

After talking with Israel Hernandez, owner of Colorado Spray Foam Insulation, LLC, they decided to use Hunstman HEATLOK 2lb closed-cell spray foam. Closed-cell foam is dense and blocks air and moisture. They chose this product for its psi strength, its vapor and radon barrier, and its R15 insulation at two inches thick.

Each slab received two inches of Huntsman HEATLOK closed-cell foam.

Israel began his career leveling concrete. He then learned to inject SPF into the spaces under sunken slabs, where it expands, fills gaps, compacts the soil, and slowly lifts the concrete back up. He soon saw that this was a fast, durable, and non-invasive alternative to replacing concrete.

Israel started his business on his own and made sure to get his SPFA (Spray Polyurethane Foam Alliance) certification. “It was a real learning curve, and I make sure my crew and I get every certification we can. This is very important to me that everyone is trained to the highest standard,” confirms Israel. Israel now has three crew members, all certified and well trained. He prefers a small, skilled team over a larger, untrained one.

Kevin Erickson is clear about his project goals, and as Israel says, “We respect all clients and projects, but it was a real pleasure working with Kevin. He is very technically minded and well-versed in spray foam, so it was great to work alongside him. He’s also a numbers guy, and so am I, so it all worked well.”

This project required Israel and Kevin to communicate closely. Kevin was a well-informed client and stayed involved at every stage. He kept Israel updated on what needed to be done, like electrical wiring and installing rebar, before the crew arrived. Israel and his team also had to adjust to the weather, sometimes working at night to stay on schedule.

Israel has three rigs he uses on various projects. He even engineered his own custom proportioner, which he proudly calls “Big Boy.”

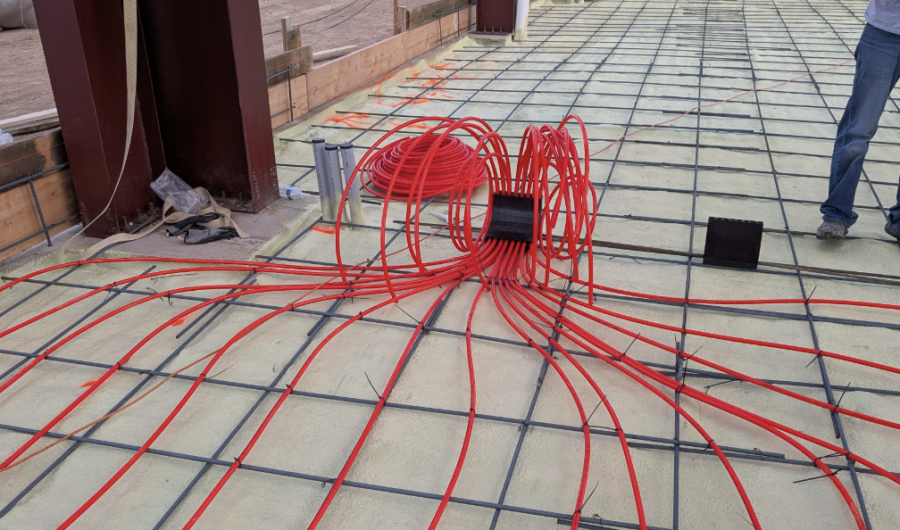

LEFT: On top of the slabs of foam, #4 rebar was installed and half-inch PEX tubing was

routed for the radiant floor system; RIGHT: A close-up look at the PEX tubing system.

The Colorado Spray Foam Insulation crew applied closed-cell foam beneath both the basement and shop/garage slabs, as well as on the shop ceilings, shop walls, and the home’s ceilings and walls—each application serving as a thermal break to reduce heat transfer. Both slabs received two inches of spray foam. Over the foam, Kevin installed #4 rebar in an 18-inch grid, routed ½-inch PEX tubing at 12-inch spacing for the radiant floor system, and poured eight inches of concrete in the garage/shop and six inches in the basement.

Spray foam insulation slows down heat transfer, which greatly reduces energy use and creates a complete envelope with an important thermal break above and below ground. Its performance is key to the passive house strategy, helping to maximize efficiency, comfort, and solar energy use.

The basement walls were waterproofed and then lined with rigid three inch Extruded Polystyrene (XPS) foam board rated at R15 (a measure of insulation's resistance to heat flow). Then two inches of spray foam were applied to the subgrade (the soil or material beneath the building) and to the rigid foam board, creating a continuous barrier. Above grade (the portion of a building above ground) will then continue with Zip-R6 sheathing for a thermal break, completing the insulation envelope. Additional spray foam will then be used above grade, wherever the air-sealing and insulation envelope is in question.

The home’s HVAC system relies primarily on hydronic tubing embedded in all concrete floors—covering the basement, shop slabs, and the two upper concrete levels.

Five air-source air-to-water heat pumps supply heating and cooling to these floors, transferring heat with minimal electrical demand. Operating at roughly 400% efficiency, they use one unit of electricity to deliver four units of heat.

Rather than generating heat, the system moves it. Warm or chilled water circulates through PEX tubing cast into the concrete, allowing the floors to act as a large thermal battery. In winter, buffer tanks supply hot water to heat the slab. In summer, chilled water circulates to keep the interiors cool.

Fan coils provide supplemental heating and cooling when needed, and an Energy Recovery Ventilator (ERV) handles balanced, efficient ventilation. The concrete’s thermal mass helps maintain stable indoor temperatures, while the closed-cell spray foam beneath the slabs prevents heat loss to the ground and contributes to overall comfort and efficiency.

The building will also use solar power, with 50kW of solar panels running the heat pumps and charging batteries. “In addition to operating the house, charging the backup battery bank, and charging EVs, solar energy can be stored as thermal energy in the concrete floors. For example, if the thermostat is set to 50 degrees in the shop slab, excess solar energy can be used to increase the floor temperature to 55 or 60 degrees instead of letting the solar panels go idle. The high thermal mass, and high-performance insulation will retain this energy into the night as the solar energy tapers off.” explains Kevin.

The 50,000-watt roof-mounted solar system powers the house, charges a battery bank and several electric cars, and stores thermal energy. The system can run off-grid for backup power and lower electric bills.

The home has several water systems for backup and performance. A well pump draws water from underground and fills a cistern in large batches, which reduces how often the pump turns on and off. This setup allows for a smaller pump, lowers electrical use, and extends the pump’s life. Rainwater collection will also help reduce reliance on the well and provide water for irrigation and other needs.

A rendering of the Erickson’s completed Passive House with 10,000 sq. ft. of living space.

Building to Passive House standards is not for the faint-hearted, as upfront costs are often higher than with traditional methods. This is mainly due to the use of specialist materials and skilled labor. Many people in the construction industry are still learning about Passive House Standards. However, as demand for energy-efficient, independent homes grows, this is changing. Projects like Kevin and Cyndi’s are helping the industry and supply chains develop, making it easier for others to take on similar projects in the future. What was once a novel idea is now being embraced by many. With energy efficiency and sustainability at the forefront of how people think about construction and the future of the earth, their wallets, and their independence.

Kevin and Cyndi expect to finish their project by fall 2026. “The project is coming along nicely, and with the installation of high-quality materials like spray polyurethane foam, we make sure that all the Passive House Standards are being met. I believe that SPF is under-recognized as a below-slab insulation. You get much more value with a continuous product that does not require a perfectly flat subgrade, no taping, no cutting around pipes and columns, and no extra vapor or radon barrier,” expresses Kevin.

As the Passive House movement expands, more people will recognize top insulation materials like SPF. “This project was a true pleasure. Kevin was so easy to work with because he knows what he wants and understands the material. He’s technically aware and passionate about energy efficiency and sustainability. It’s great to have clients like Kevin who have done their research and know the benefits of foam,” confirms Israel.

Israel is finding that he is working more and more with clients who are adhering to the Passive House standards due to rising energy costs, climate change concerns, and a demand for healthier, more comfortable buildings. With people like Kevin who are aware of SPF’s long- and short-term benefits, this could be a growing movement.

Disqus website name not provided.